Northern Cape mine smooths flow with Weba Chute

A rendered image of the jaw crusher feed chute

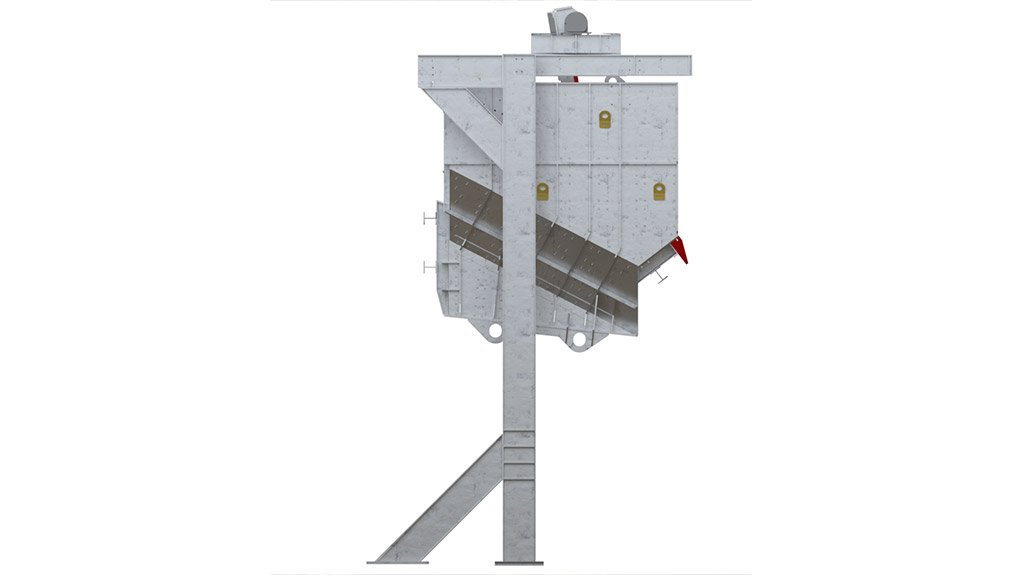

A side view of the jaw crusher feed chute

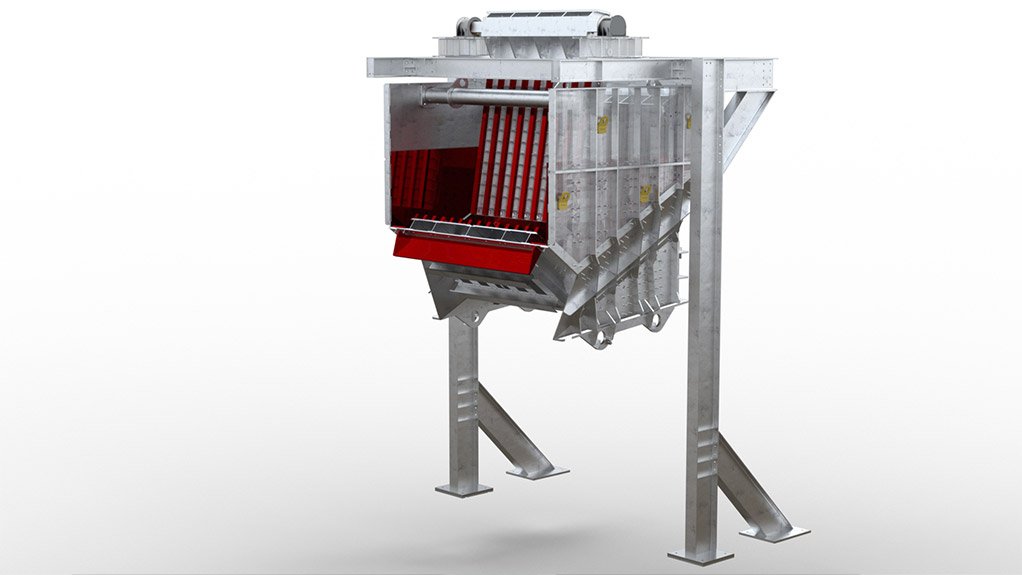

A rendered image of the apron feeder discharge chute

Specialist transfer point company, Weba Chute Systems is working with a mine in the Northern Cape to improve material flow. The mine has ordered two custom engineered chutes from Weba Chute Systems, which are expected to improve efficiency at the transfer points.

According to Weba Chute Systems’ Regional Manager for the Northern Cape, Arnold Archer, the contracts are for an apron feeder discharge chute and a jaw crusher feed chute. Archer says the company had previously supplied the mine with a SAG mill feed chute, and had collaborated successfully to improve performance within that application.

With run-of-mine material at the mine including large lump sizes of 800 mm to 1,2 m, there is a high risk of blockages if the chutes are not purpose-designed, he argues. The high velocity of the material can also cause considerable damage to chutes as well as create excessive dust.

To inform Weba Chute Systems’ designs, the company’s team uses technical questionnaires to help gather information from the customer on a range of variables. This includes factors like lump size indicators, belt speeds, feed rates, moisture content and material velocity. The application-specific data paves the way for a design that optimises flow and equipment life.

“On the apron feeder discharge chute, for instance, we designed a swing door that will absorb most of the impact of big lumps moving at high velocities,” he says. “This also helps to protect the wear plates on the jaw crusher.”

The aim of the design will be to assist the mine reduce the incidences of chute blockages, spillage and excess dust – making the process more streamlined and less labour intensive. He points out that the mine aims to achieve higher uptime through optimal chute performance. The reduction in spillage and dust also contributes to the mine’s high standards of health and safety.

“Our philosophy is that every transfer point on a mine has its own specific challenges, so the chute for each transfer point will be different to the next one,” he says. “We work with customers to understand the detail of their material flow through these points, so that our design takes all the key factors into account.”

He notes that most mines will have the necessary data gathering systems in place to inform the correct chute design – as they have tachometers on their conveyors, blocked chute detectors and feed monitors. The issue is just that this information is not always systematically considered during chute design.

“We are proud of the chutes we design and manufacture, and stay close to our customers to ensure that the chutes’ performance is up to expectation,” Archer explains. “Our staff is passionate about getting everything right, and being there to follow up where necessary.”

Among the improvements made on the SAG mill feed chute at the mine, for example, were changes to the liner composition and pattern. Rather than removing all the liner segments to reach the middle row, the pattern change now allows this row to be removed without loosening all the other liners, he says.

Weba Chute Systems can also install its own chutes, but provides supervision and assistance where the mine arranges the installation itself, he concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation