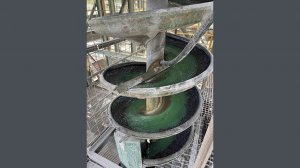

Multotec's SX4 degritting spiral reduces carbon costs for mining operations in West Africa

Amid tough economic conditions, Multotec has responded to a challenge faced by gold operations in West Africa which were dealing with the high costs of activated carbon used in gold processing. To help mitigate these costs, the Multotec SX4 spiral commonly used in coal processing was adapted for a different application by introducing it into gold processing market. The use of the SX4 spiral achieved up to 95% removal of contaminants from carbon and proved to be an efficient and cost-effective solution.

According to Godwin Dzwairo, General Manager for Multotec in West Africa, several mining operations in the region exploit low-grade gold reserves and thus push more tonnage of mined ore through their mill circuits to increase their yield. However, this compromises milling efficiency as a result.

“This means that they run up costs in terms of activated carbon usage during the Carbon-In-Leach (CIL) process, which is an integral part of gold extraction. The carbon subsequently becomes contaminated with non-gold bearing material such as silica, sand and woodchips and these need to be removed,” says Dzwairo.

He explains that Multotec’s SX4 can remove up to 85-95% of waste material from the carbon, which also improves the efficiency of downstream processes and reduces the amount of reagents needed during the final elution and gold recovery process, thus saving further costs.

Accounting requirements

“Additionally, metallurgical accounting requirements are becoming increasingly stringent, meaning that gold extracted from ore must be accurately accounted for using analysis of the rock, slurry, carbon and final product. When the carbon is associated with material that is not gold bearing, this material can be carried over to the elution processing phase and the weight can distort gold accounting,” says Dzwairo.

“So, by taking the waste material out of the carbon before the next step, miners can account more accurately for gold, and their downstream processes will be more efficient because the contaminants have already been removed. Typically, waste material makes up about 10-20% of the product weight, so removing it allows you to better estimate the weight of the gold yield.”

The SX4 spiral is constructed with materials that ensure a high-quality product with a longer life that is low maintenance and low cost.

According to Refentse Molehe, Process Engineer at Multotec Group, the SX4 spiral is a cost-effective solution because it relies solely on water and gravity for the separation process and does not require any energy source or chemicals. Implementation of the SX4 spirals in gold operations is done with ease through the option of retrofitting the spiral into existing operations alternatively there is the flexibility of the use of a compact modular design.

Cost-effective and efficient

“This isn’t a new technology, as it has previously been used in coal mining, but we saw an opportunity and adapted it for a new purpose,” she says. Multotec’s spirals team completed the design drawings for the SX4, whereafter the company’s field service team and contractors managed and assisted with the installations at the customer’s plant.

Molehe adds that while the high cost of carbon is not a new problem facing the gold mining sector, it has in recent times been exacerbated by the increased economic pressures on gold production.

To date, Multotec has completed SX4 degritting spiral installations at three gold mining operations in Ghana, and at a gold mine in Guinea, and has also engaged with a potential customer in Burkina Faso that is seeking to improve efficiencies.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation