Scanner finds copper-rich mineralisation

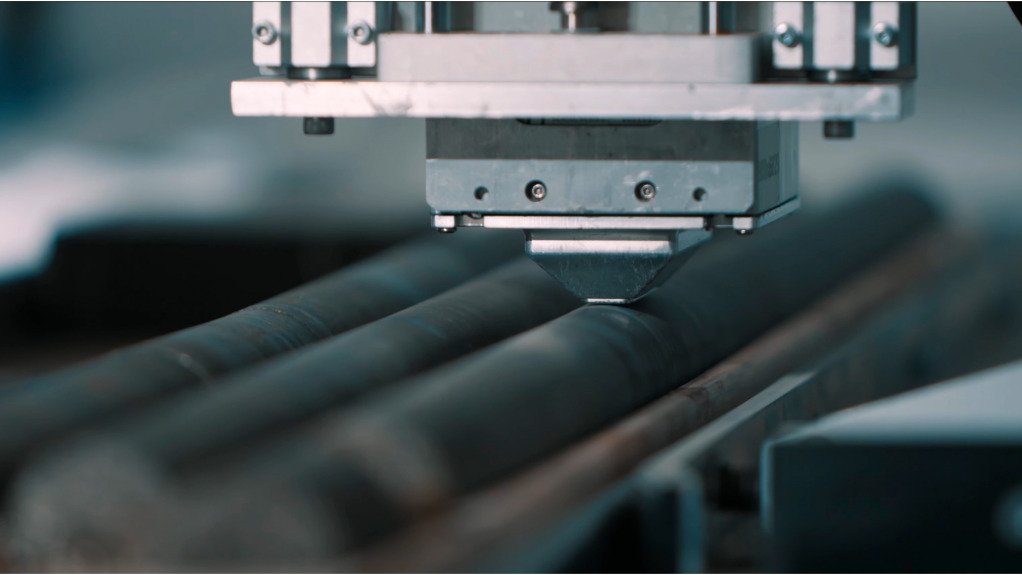

DEEPER INSIGHT The TruScan system integrates various sensors to collect real-time, high-resolution geochemical data

Mining technology provider Veracio’s TruScan core scanning system has facilitated the generation of geological insights instrumental to discovering diversified explorer and developer Foran Mining’s Bridge target zone, which is adjacent to Foran’s McIlvenna Bay copper development project, in the province of Saskatchewan, in Canada.

Since the start of its partnership in 2022 with Veracio, Foran has deployed the TruScan system on-site as part of its ongoing exploration at its flagship McIlvenna Bay project to better understand the intricate geological complexities of the existing resource and the Tesla discovery, explains Foran exploration VP Erin Carswell.

McIlvenna Bay is a volcanic- hosted massive sulphide deposit with a 44-millon-tonne resource. The project is complemented by the Tesla and Bridge Zone discoveries, both of which are key focal points of Foran's exploration and expansion efforts.

She elaborates that the deposit has gone through high grade metamorphism and multiple deformation events, resulting in a fine grained texture that makes it difficult to differentiate between primary lithologies and varying alteration styles.

The use of the TruScan system has resulted in rapid advancements in Foran’s understanding of the Tesla Zone target, as it allowed Foran to piece together the original stratigraphy and integrate the geology with what was already known at McIlvenna Bay.

The drilling season for the Tesla Zone is limited to two-and-a-half months during winter as a result of drilling rigs needing to sit on the frozen lake. Therefore, Foran requires rapid data delivery for informed decision-making throughout the short drilling season.

Veracio chief alliance officer Annelie Lundström explains that without access to detailed and quick geological information, geologists would have to wait longer periods for laboratory results, which can result in significant delays for a project.

By providing detailed geochemical and structural insights, TruScan enhances geologists’ understanding of mineralised zones, facilitating more accurate resource estimations and the refining of drilling strategies.

This technological integration expedites real-time interpretations and improves drilling efficiency by optimising the placement of subsequent drill holes and also serves to reduce the wasting of resources.

Carswell emphasises the importance of confidence, particularly in defining chemostratigraphy. With this understanding, geologists can efficiently analyse TruScan data by feeding it through custom classification diagrams designed to identify specific lithologies, such as felsic volcanics, gabbros and sediments.

“It allows our geologists to verify what they are seeing in the rocks and spend more time on the real-time interpretation, which ultimately results in better understanding and better exploration outcomes,” she explains.

How it Works

The TruScan system integrates various sensors to collect real-time, high-resolution geochemical data, including matrix-calibrated X-ray fluorescence (XRF) and camera imagery of wet and dry samples.

The system uses light detection and ranging technology to generate three-dimensional models of core samples, allowing precise positioning of sensors for optimal data collection quality.

TruScan features high-resolution photography and can scan 80 m to 100 m of core per 12-hour shift.

TruScan also removes subjectivity from geological analysis.

TruScan provides comprehensive data on orebody chemistry, lithology and structure, empowering mining companies to optimise extraction strategies and increase profitability.

The trailer-based system is designed for reliability in harsh conditions, ensuring consistent performance in various environments, offering granular insights in a timely manner.

How it Works

XRF core scanning technology analyses drill core and chips for a wide range of elements, with the XRF technology bombarding samples with high-energy X-rays, which causes the atoms in the sample to become excited and emit secondary fluorescent X-rays, which generates a spectrum which can be analysed to determine elemental composition of a core sample.

Veracio’s in-house software compares the spectrum to calibration material to convert the spectrum data into quantitative element concentration data, explains Lundström.

Veracio collaborates closely with clients to develop site-specific calibrations dependent on environment conditions and application for the purpose of achieving accurate quantitative data.

While clients face various challenges unique to their project, Lundström notes that clients often experience difficulties associated with processing large volumes of core data and require automation to process data more efficiently.

Paired with Veracio’s Data + artificial intelligence tools, Tru-Scan can generate data to automate core logging among other capabilities, reducing errors and accelerating the process.

Lundström points out that drill core logging is traditionally subjective, as it relies on human sight to determine the elements in a sample.

However, using TruScan, geo-logists have access to in-depth data that can detect elemental changes in the rock which might not be visible to the naked eye.

While acknowledging that TruScan is an invaluable tool in exploration, Carswell emphasises that it serves as an enabler rather than a replacement for geologists.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation