New technology introduced at Mining Indaba

IMPROVED PROJECT PLANNING WorleyParsons RSA’s integrated design project platform provides a visual five-dimensional design scope that incorporates schedule and cost

Engineering company WorleyParsons RSA will use the 2017 Investing in African Mining Indaba, which it describes as an ideal platform for showcasing and progressing ideas pertinent to Africa’s mining industry, to discuss its new five-dimensional (5D) project design platform technology with key players in industry.

The technology, which has been developed over the past five years, is in line with the company’s aim to help customers increase accuracy and efficiency in their operations while reducing risk. The platform integrates sophisticated technology tools to provide a greater degree of predictability throughout the life cycle of an asset and, ultimately, increase profits, even in the ongoing volatile commodities market.

WorleyParsons RSA mining GM Henry Jonker notes that, while there are numerous powerful engineering design processes and programmes that are used to improve efficiencies in mining and other sectors, WorleyParsons RSA is one of the first engineering consultancies in the mining sector to develop methods that integrate these products to reap the benefits of their combined use.

“Essentially, we’re taking individual puzzle pieces and figuring out how to slot them together to show our customers the bigger picture of their project. WorleyParsons RSA does not develop new systems – we modify the best available standard systems instead so that they can be easily integrated in existing operations.”

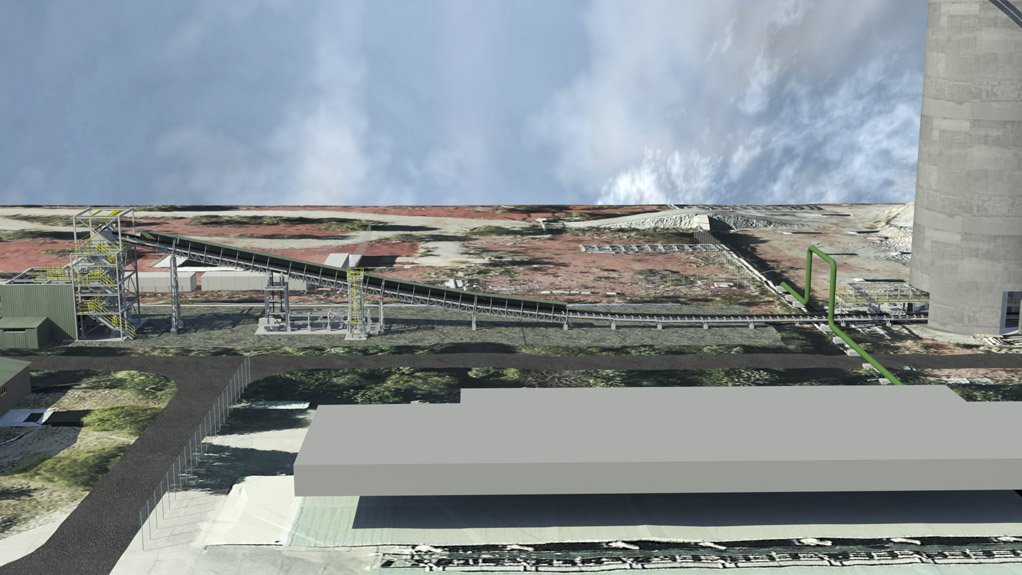

The company’s integrated design project platform was developed by integrating three-dimensional (3D) intelligent design data mapping with more than 20 different engineering design processes and programmes to create a visual 5D design scope that incorporates schedule and cost. This 5D integrated project platform approach has been applied to several projects and is proving its worth in saving customers time and money.

WorleyParsons RSA engineering manager Mushir Khan highlights, for example, that the application of the integrated technology to a front-end engineering design contract for a 100 000 t/m Merensky concentrator at a North West platinum mine last year ensured the successful and expedient completion of the project.

“This is the first project where the integrated technology was applied to its fullest potential and it has proven to work highly efficiently. Using the 5D technology, we quickly identified value improvements and recognised how to optimise the previous concentrator design. Optimisation is usually done after a project has been completed. In this case, we used 5D technology in parallel with optimisation, saving the customer time and money while pinpointing risks and value-improvement propositions.”

Khan explains that the norm is to first complete a feasibility study and then address all the risks identified during the feasibility stage. Thereafter, value improvements are established to limit costs and improve construction schedules.

Using the integrated technology model at the North West project enabled WorleyParsons RSA to conduct the feasibility study and value improvement simultaneously, and determine 90% of the dimensions and costs. Subsequently, this allowed for the detailed- engineering phase to be undertaken quickly and at a high level of accuracy, resulting in a predictable construction cost.

Khan highlights that this high level of accuracy is obtained by plugging in real-time costs into a 3D parametric design module to create a cost-based estimate. “We can now seamlessly integrate 3D parametric design in a 5D platform, making detailed engineering much easier and quicker to provide our customers with a far clearer overview of their projects.”

The company has been using parametric design for bulk materials handling to simulate processes based on specified parameters. Parametric design is a type of 3D modelling that can demonstrate how a product or process will function based on varying parameters or values. Parametric design models allow for flexible designs and 3D visualisation of a process as parameters change, and facilitate faster completion of designs.

“In future, WorleyParsons RSA will apply integrated technology as a standard offering on new projects,” says WorleyParsos RSA business development executive Murray Macnab, adding that at a “very low” additional cost, customers can also buy an operational model as part of the offering.

“With our integrated technology module, we can create the framework and groundwork to deliver a project to a predictable construction deliverable . . . we can also . . . apply that module to existing operations,” adds Khan.

He points out that all the data generated is electronic, eliminating the chance of paperwork getting lost or damaged. Cost models can also be imported directly to the integrated technology platform and all data from a design model, such as parts suppliers and operational information about parts, can be uploaded to a customer’s system. The data can also be used for simulation purposes.

Macnab adds that, as a project is established, a vast amount of data is generated and, as one of the jigsaw pieces of WorleyParsons’ integrated technology offering, the company can use this data to offer customers a large degree of predictability over the life cycle of a project, eliminating guesswork.

“We cannot predict the selling price of commodities at any given time, but we can predict productivity and maintenance schedules that can prevent unexpected shutdowns by using available data, generated during the feasibility and engineering stages.

Our objective is to ensure that all our services focus on reducing risk while quantifying data to increase productivity,” concludes Macnab.

The Mining Indaba is set to run from February 6 to 9 at the Cape Town International Convention Centre.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation