Mines investing R46m to put an end to fall-of-ground fatalities

Action plan to end fall of ground fatalities covered by Mining Weekly's Martin Creamer.

R46-million being invested to end fall-of-ground fatalities.

Research and development to end fall-of-ground deaths.

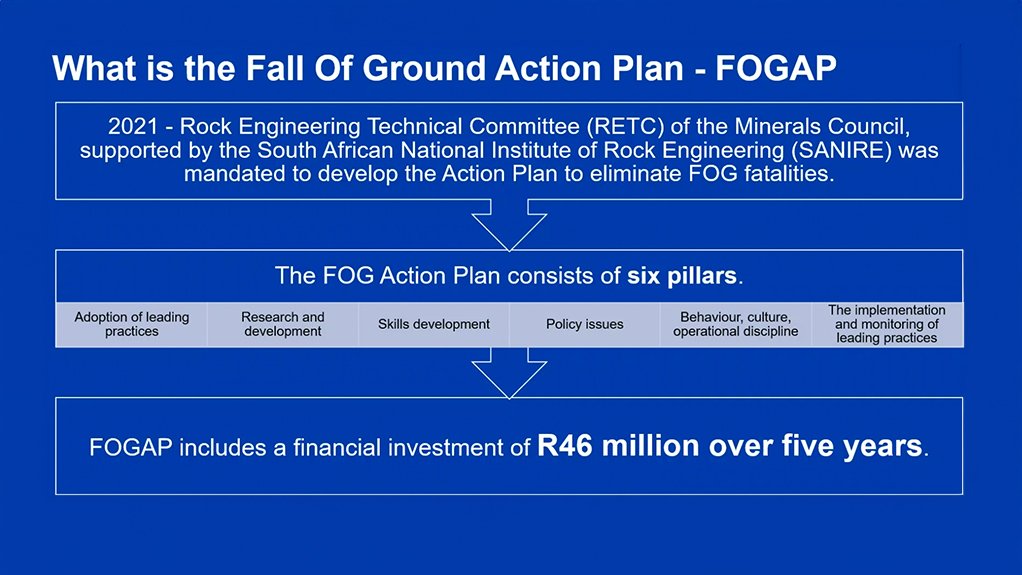

JOHANNESBURG (miningweekly.com) – South Africa’s mining industry is investing R46-million in an action plan to eliminate fall-of-ground (FoG) fatalities.

The FoG action plan is being implemented through Minerals Council South Africa with the assistance of its Rock Engineering Technical Committee, and supported by the South African National Institute of Rock Engineering, the Association of Mine Managers of South Africa, and the South Africa Colliery Managers’ Association.

“We know it is possible to restrict fall-of-ground deaths to six and so certainly, from where we are today, the next breakthrough must be zero fatalities. We cannot aspire for anything less than that,” Minerals Council South Africa CEO Mzila Mthenjane emphasised during Friday’s day of learning at Emperors Palace Convention Centre, east of Johannesburg. (Also watch attached Creamer Media video.)

In 2022, the lowest FoG fatalities of six were reported, which was 73% down on the previous year and a record low that still stands.

Highlighted during the well-attended event, which was covered by Mining Weekly, was the need to establish improved underground workplace visibility and permanent workface aerial mesh protection, and to investigate the introduction of hydropowered drills and drill guides.

The plan’s six pillars are adoption of leading practices, research and development, human resource development, policy considerations, which are ultimately in the hands of government, operational discipline, and the close monitoring of the expenditure of the R46-million.

“It's a very good vision and we constantly review it,” Minerals Council safety and sustainability deputy head Lerato Tsele told the audience, who were given the opportunity to pose questions.

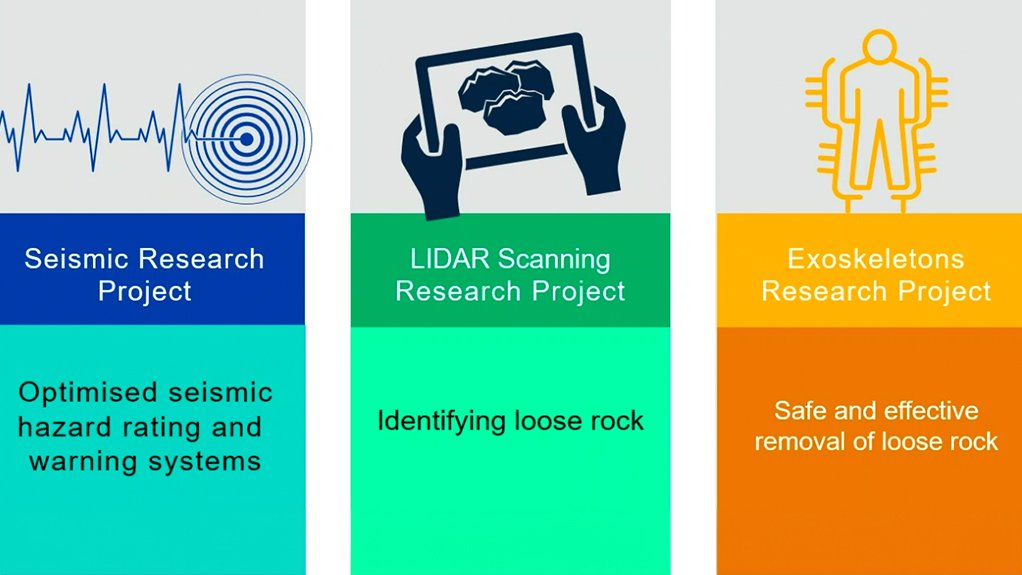

Set in motion has been research into hazard warning systems, loose rock scanners, and wearable exoskeleton devices to be worn when removing that loose rock.

Exoskeletons reportedly bolster human performance in physically demanding tasks by supporting various body parts, including the hands, lower and upper back, legs, shoulders and arms, which is said to reduce the amount of energy required when lifting and carrying heavy objects and holding heavy tools.

Crucially, the FoG action plan also comes with a promising skills development project plus the updating of learning material.

The event began with a moment’s silence in remembrance of FoG fatalities and injuries, 60% of which occur in the stope face, as well as in tunnels and gulleys.

This is why considerable innovation and technology is being directed towards improving the safety of these areas, as part of the plan being led by a CEO Zero Harm Forum.

For the past 20 years, the number of FoG fatalities has been reducing, with the first fall below 100 in 2004, when 96 deaths occurred.

Six years later in 2010, FoG fatalities fell below 50 and the next breakthrough was in 2015 when FoG fatalities were fewer than 25.

But it appears to be getting tougher, reflected in the ten latest deaths.

“There are ups and downs, but it's not a time to give up,” said Mthenjane.

“There’s a need for those who will look ahead in terms of what is upcoming that will be useful, whilst we implement current technologies that are proven … and what is going to become much more important moving forward is behaviour,” he added.

“Perhaps not too much of a focus on when we're going to get there. It's not a race. It’s something that is urgent, and it's something that we do need to achieve sooner rather than later because it means that more people will be going back home to their families. Part of the solution lies in how we leverage innovation and technology,” he said.

The Isidingo drill has proven its capability. It is much lighter than the pneumatic drill, more energy efficient, considerably quieter, and easier to handle.

What these new technologies are showing is that mining is no longer about physicality and lighter equipment technologies are enabling gender-neutral participation.

Hydropower is lending precision drilling in the forms of consistency of fragmentation and speed.

The amount of time spent underground can be shortened while still achieving the full amount of work that is required.

The next step is to develop drill guides that are adaptable to all underground situations.

The journey to zero fatalities is demanding best practice and a collaboration where the commitment remains safety first – always.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation