Miners can breathe easy with Trysome’s ISO-compliant air filtration solutions

ISO Working Group lead Jeff Moredock discusses the importance of ISO 23875 compliance and why South Africa needs Trysome.

South Africa needs Trysome Auto Electrical Engineering to ensure the health and safety of mining equipment operators through the adoption of international best practice air-quality control systems, says ISO Working Group lead Jeff Moredock.

Established in 1991, Trysome is committed to developing and innovating auto-electrical and safety compliance pro-ducts. Many of the company’s state-of-the-art safety com-pliance systems have been adopted and installed at mines across Southern Africa.

The Gauteng-based, heavy-duty auto-electrical compo-nents supplier is well equipped to deliver air filtration solutions that comply with the new ISO 23875 cabin air standard and tackle the most intensive, debris-laden working environments.

Published in February 2021, the international standard highlights the need to maintain good air quality in an operator enclosure over the life of mining equipment. ISO 23875 emphasises the importance of regulating oxygen levels to avoid fatigue events brought on by high carbon dioxide (CO2) content, and preventing lung disease caused by exposure to high particulate matter (PM) concentrations.

To do so, the standard stipulates a maximum allowable CO2 level of ambient CO2 + 400 parts per million and a maximum respirable PM concentration of less than 25 mg/m3 of air at the start and/or end of a decay test, with a maximum 120-second delay time. Operator enclosures must also maintain minimum pressurisation of more than or equal to 20 Pa, even when the heating, ventilation, and air-conditioning are turned off. A real-time operator cabin monitoring system is also critical and must include an audible alarm for CO2 and pressurisation to alert the operator when levels exceed the permissible threshold.

“We must provide con-sistently oxygen-rich, low particulate air over the life of a machine until it is taken out of commission. Trysome is capable of retrofitting existing and new mining equipment to comply with ISO 23875 and does a remarkable job,” explains Moredock.

Through its partnership with leading air filtration sol-utions provider Sy-Klone International, which has more than 30 years’ experience and 100 air filtration and pre-cleaning patents, Trysome offers world-leading air-quality and control systems for heavy equipment cabins.

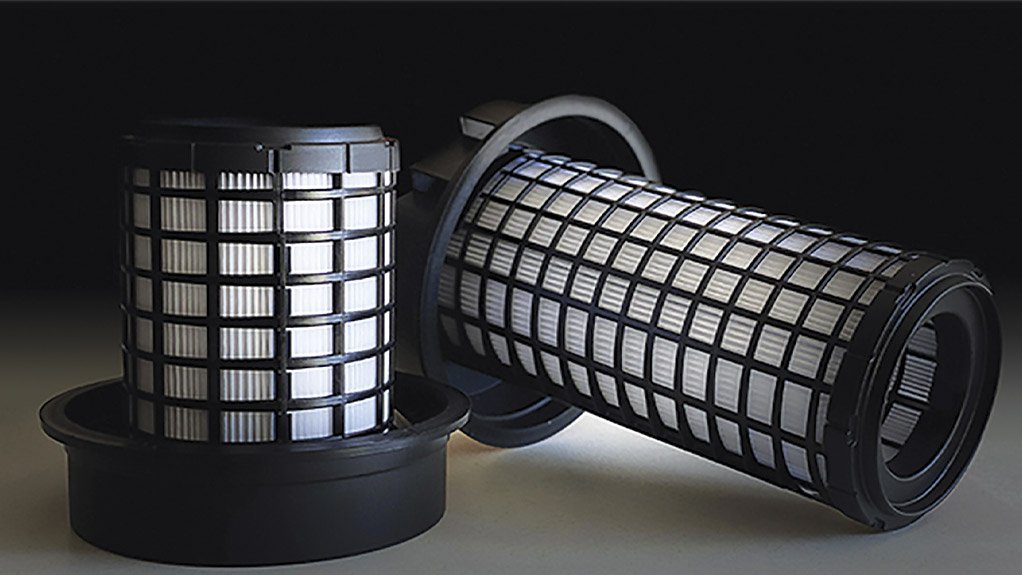

For example, Sy-Klone’s RadialSHIELD® HEPA filters deliver higher filter efficiency while maintaining needed airflow levels, and are 99.95% efficient at the most penetrating particulate size.

ISO 23875 requires that a filter meet more stringent evaluation criteria. Typically, an ISO 15 E or higher efficiency, or an ISO 35 H HEPA filter is required for compliant cabins.

“It’s very helpful if you have a company like Trysome that understands what’s necessary from an engineering perspective,” adds Moredock.

While ISO standards are not regulated by law, they are international best practices. Therefore, global mining companies active in South Africa have already adopted ISO 23875, Moredock says, emphasising that education is key to further driving the adoption of the standard locally.

“This education process has already started in South Africa. We’re going to continue to build on the education framework that we’ve put in place, as this is key to the adoption of the standard and changing culture.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation