Support to ensure optimal performance

THOROUGH MAINTENANCE MBE Minerals is capable of undertaking ongoing equipment condition monitoring, maintenance and service support

With mining operations remaining under pressure to optimise plants, original-equipment manufacturers (OEMs) and suppliers must be more dynamic and focused in terms of their overall market offering, says minerals beneficiation technology supplier MBE Minerals SA MD Johannes Kottmann.

He says that the company’s strong relationship with and understanding of its customers’ operations allows MBE Minerals to provide optimum value support and services, all of which is aimed at ensuring that operations perform optimally.

“MBE Minerals’ support options are customised to suit specific customer requirements and can range from basic maintenance contracts, which would typically include on-site service personnel, to consignment stock facilities, progressing right up to comprehensive service-level agreements (SLAs). At this level, support is provided through fully fledged regional service centres capable of undertaking ongoing equipment condition monitoring, maintenance and service support.”

Kottmann says customers are able to leverage the expertise and in-depth experience MBE Minerals SA has acquired across the full spectrum of services to a large footprint of customers. “With an OEM supporting the equipment in the plant directly, it is possible to implement efficiency improvements as a result of ongoing input and interaction with the plant personnel. In addition, training is undertaken that benefits the plant personnel both in terms of operator needs and maintenance.”

He adds that the maintenance of equipment in mineral processing plants is as important as its optimum functioning and a multidisciplined approach needs to be instituted when designing a plant. Kottmann maintains that OEMs should be tasked with the continued and consistent maintenance of equipment in the plant to ensure that it is carried out cost effectively and downtime is reduced.

“We have seen a trend developing within the industry, whereby customers are moving away from maintaining plants in-house to an SLA or life-cycle contract with the OEM. This implies that the manufacturer is not only selling a piece of equipment but is also supplying the customer with a comprehensive maintenance plan,” Kottmann explains.

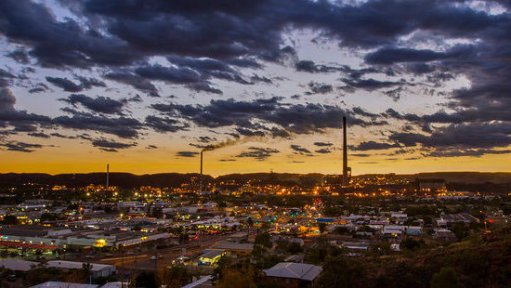

“Coupled with this is the importance of the OEM’s location in relation to its customer’s operations. We currently operate a fully fledged service centre in Kathu, in the Northern Cape, to cater for the iron-ore and manganese operations and, in Middelburg, Mpumalanga, to service various customers in the coalfields.”

As a result, the MBE Minerals teams have developed first-hand knowledge of how its equipment is operating within the various plants, enabling application-specific design improvements that result in an enhancement in the operational life and efficiency of the equipment. The company’s locality in close proximity to its customers also allows the company to provide a rapid response technical assistance and maintenance service, Kottmann concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation