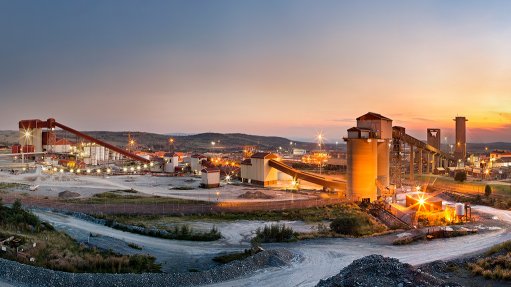

Kamoa-Kakula Phase 1 concentrator reaches steady-state, sets daily production record

TSX-listed Canadian mining company Ivanhoe Mines reports that the 3.8-million-tonne-a-year Phase 1 concentrator plant at its Kamoa-Kakula mine, in the Democratic Republic of the Congo, has met all design criteria and is now operating at steady-state, setting a new daily production record of about 729 t of copper.

Work is under way to further enhance the plant’s operating performance – in October, the operation produced 323 368 t of ore at an average feed grade of 5.89% copper, thereby exceeding the monthly design run rate of 316 667 t.

Production during the last ten days of October averaged 611 t a day of copper in concentrate, while on October 25, a new daily production record of 729 t of copper in concentrate was achieved.

Therefore, a record 16 211 t of copper in concentrate was produced (filtered product) in the reporting month ended October 20, when the average floated concentrate copper grade was 51.5%.

Further, the operation’s fifth full month of production neared the Phase 1 target output of 16 666 t a month, or 200 000 t/y; while total year-to-date copper in concentrate production was 62 974 t as of October 20, for delivery to either the Lualaba Copper Smelter near Kolwezi, or to international markets.

Copper flotation recoveries averaged 85.1% in October. The Phase 1, steady-state-design copper recovery is about 86%, depending on ore feed grade.

Kamoa Copper CEO Mark Farren says October was an important milestone month for the miner, in many ways. “The project team managed to commission the second concentrate filter press which we believe will create a lot of flexibility downstream.”

As a result, he says, concentrate volumes can now be increased to match the potential of the front end of the concentrator plant (milling), enabling recoveries to be tweaked by increasing the mass pull to the concentrate thickener.

While it took a few weeks to fine-tune the second filter press, the plant performance met steady-state expectations despite intermittent regional power outages during the first three weeks of October.

“Barring any major issues, the operational team is confident that we will reach the upper end of our production guidance of between 90 000 t and 95 000 t of copper in concentrate in 2021,” says Farren.

Meanwhile, also during October, the Kakula mining team encountered a significant inflow of water at the northern perimeter drift, but he says this event was “well managed” and monthly underground production volumes were maintained at about 400 000 t.

PHASE 2

Ivanhoe also reports that construction of the 3.8-million-tonne-a-year Phase 2 concentrator plant is progressing well, with the overall project about 60% complete – with engineering and procurement activities effectively complete, and fabrication more than 92% complete.

On October 22, the Phase 2 project construction team reached four-million lost-time-injury-free hours – this milestone underscoring the strict safety culture of the Kamoa Copper construction team and contractors.

Going forward, the main construction focus remains on the erection of structural steel and the installation of platework and equipment.

Both ball mills have been lifted into position and installation of the girth gears is currently underway, with the mill installation expected to be complete by the end of the year.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation