Mobile crusher manufacturer adds to portfolio

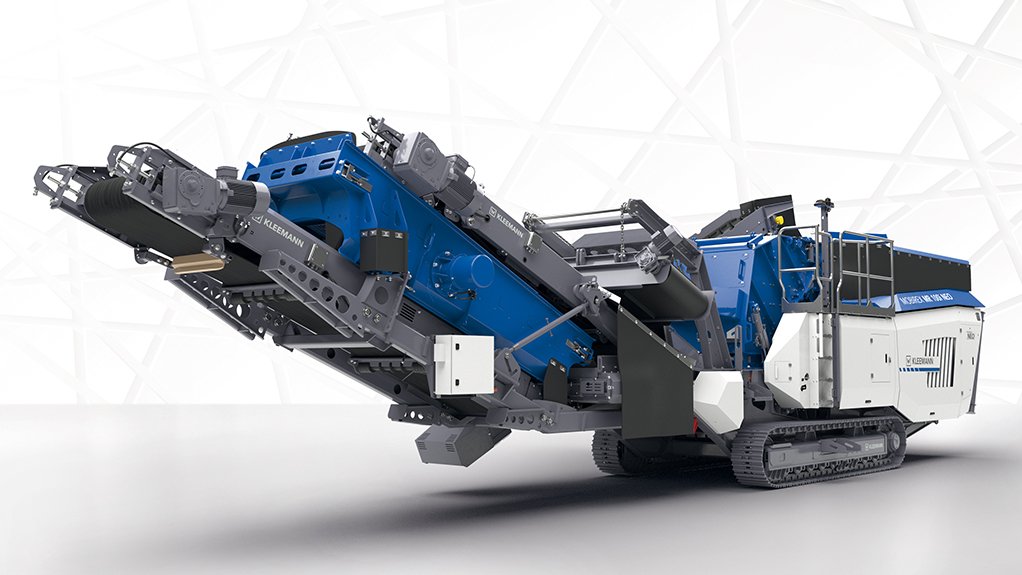

GETTING TO THE CRUNCH OF THINGS The new Kleeman MOBIREX MR 100(i) NEO and NEOe range of crushers will be rolled out early next year

Mining and construction solutions provider Wirtgen Group’s Kleemann brand announced in August that it will launch its mobile impact crusher, the MOBIREX MR 100(i) NEO and NEOe gradually, starting with the European and North American markets, in the first quarter of 2024.

Mobile crushers are used on a regular basis by surface and opencast miners to process materials.

The NEO range of crushers is the new efficient, compact class from Kleemann, which aims to extend the company’s global crushing and screening product portfolio, with the MOBIREX MR100(i) NEO and NEOe being the first series member of the new NEO line to be released to market.

According to Kleemann, the NEO machines are efficient, powerful and flexible, while all-electric operation is possible with the NEOe variant, which, depending on the application area, can be deployed using its E-DRIVE concept and thus, not emit carbon dioxide emissions.

Nonelectric crushers from Kleemann are powered using the company’s tried-and-tested diesel-direct drive – D-DRIVE – powertrain.

Owing to its compact dimensions and a low transport weight, the MOBIREX MR100(i) can be used flexibly, quickly and in a wide variety of applications.

Operation in tight spaces on work sites, or in frequently changing places of work, is also easily possible, according to Kleemann.

Operation ranges from different recycling applications, such as the processing of concrete, rubble and asphalt, to the processing of soft to medium-hard natural stone.

Quality of material produced is ensured not only by the powerful crushing unit with its four-legged rotor with a large impact range and versatile rotor ledge options, but also by the optional 4 m2, single-deck secondary screening unit. This makes it possible to produce a classified final grain size, and by making use of an optional wind sifter, the final product quality can be further increased.

Kleemann notes that as a result of the NEO range’s SPECTIVE operating unit being specially tuned to the functions, operation of the MR100(i) NEO and NEOe is simple and intuitive.

With SPECTIVE CONNECT, crusher operators are presented with all relevant data, including equipment speed, material consumption values and fill levels through a mobile device, such as a smartphone or tablet. This information is prepared in a clearly arranged manner, Kleemann states.

SPECTIVE CONNECT also offers detailed troubleshooting aids to assist with equipment servicing and maintenance.

A unique feature in this machine class, Kleemann points out, is the fully automatic crusher gap adjustment and zero-point determination.

Zero-point determination compensates for wear during crusher start and also helps ensure a homogeneous crushing product is consistently produced. Wirtgen Group states that drilling and blasting, earthwork and rock operations are no longer “state of the art” mining solutions for surface deposits. The company posits that surface mining offers a more economically efficient and environmentally friendly solution, as it is capable of cutting, crushing and loading rock in a single working pass.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation