Company revolutionises IIoT, predictive maintenance

CONNECTIVITY & INSIGHTS SEW-EURODRIVE’s Smart App connects the user to the data gathered and the insights that follow

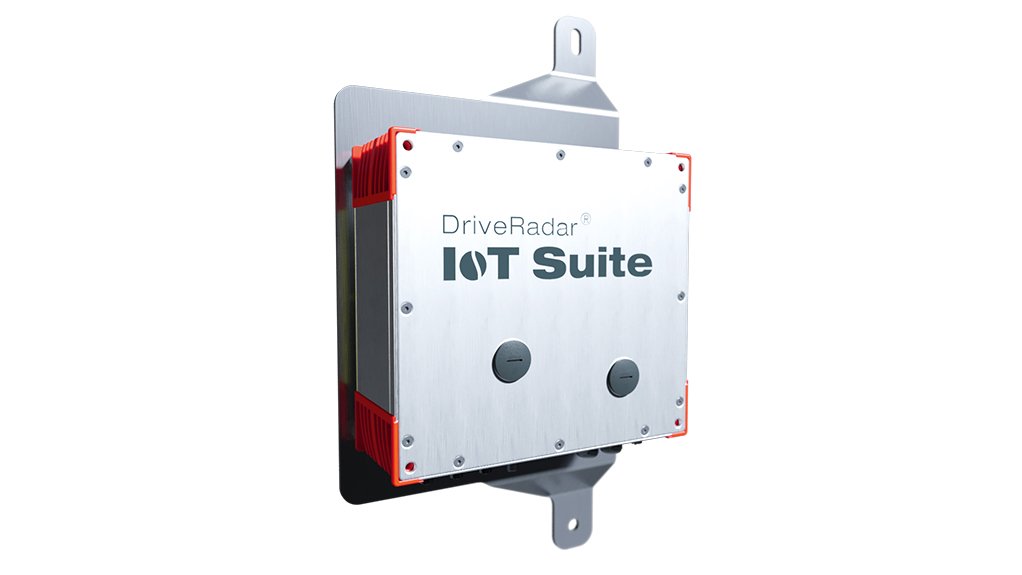

PARAMETER ANALYSIS With the DriveRadar range for industrial gear units, all operationally relevant mechanical parameters are recorded and analysed

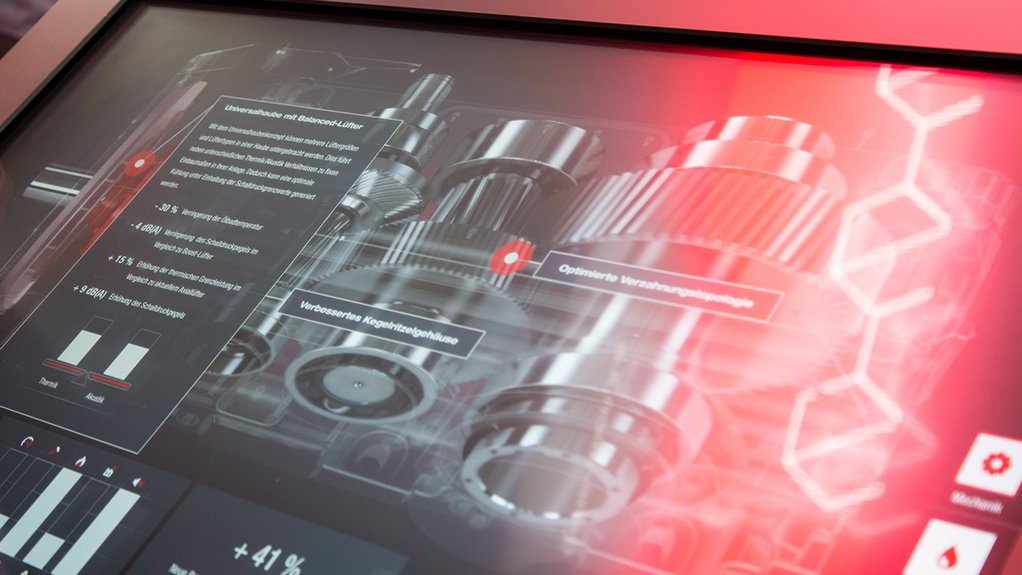

DIGITAL TWIN The digital twin of the product is already created in the development phase and is complemented with valuable information during the entire product life cycle

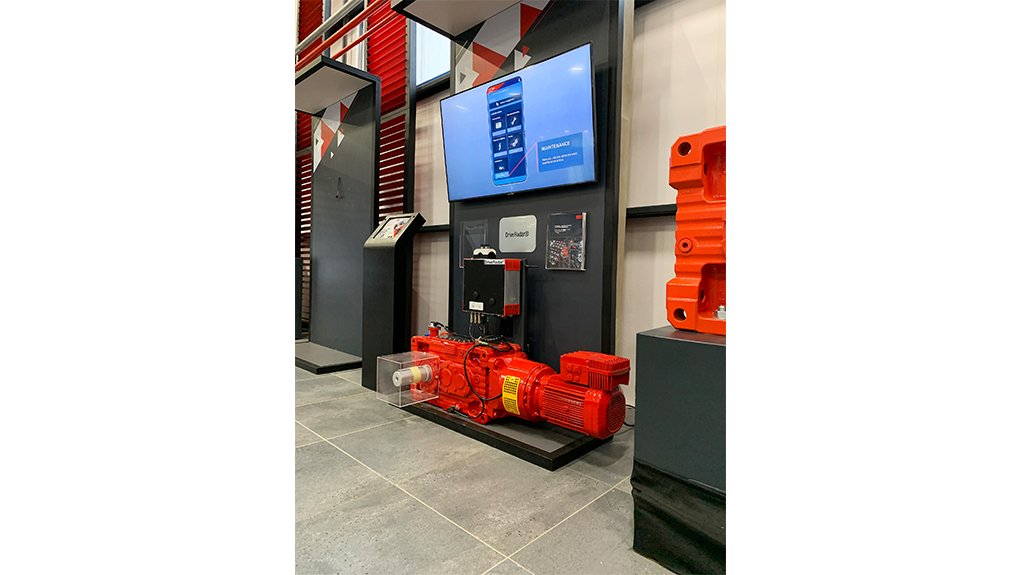

SHOWROOM DEMONSTRATION The SEW-EURODRIVE showroom in Aeroton, which is open to industry, hosts a demo of the DriveRadar system

ANDREAS MEID DriveRadar offers integrated digital service offerings and products with the added value of in-depth analysis and monitoring

Unplanned downtime is a major challenge for companies active in manufacturing, as it not only leads to lost productivity and revenue but can also result in additional costs, owing to emergency maintenance and repairs.

However, with advancements in Industrial Internet of Things (IIoT) technology, companies can now monitor their equipment in real time and predict potential failures before they occur.

One such technology is available through automation specialist SEW-EURODRIVE, whose DriveRadar IIoT is revolutionising the way manufacturers approach predictive maintenance.

The cloud-based IIoT solution uses real-time data from connected equipment to provide insights into manufacturers’ machinery performance, and can detect anomalies and predict potential failures, enabling operators to take corrective action before a breakdown occurs.

“This results in improved equipment uptime, increased productivity and reduced maintenance costs,” says SEW-EURODRIVE business development engineering head Andreas Meid.

The DriveRadar system comprises sensors that are installed on the equipment, which collect and transmit data to a cloud-based platform for analysis and monitoring.

“With the functional levels Smart Product (drive components), Smart System (system solutions) and Smart Process (plant processes), DriveRadar offers integrated digital service offerings and products with the added value of in-depth analysis and monitoring of drive components, systems solutions and processes,” he adds.

The data is then processed using machine learning algorithms to detect patterns and anomalies that may indicate potential issues. The system can also integrate with existing equipment and software, making it easy to implement into existing manufacturing operations.

One of the key benefits of DriveRadar is its provision of real-time notifications and alerts when anomalies are detected, consequently enabling operators to quickly respond to potential issues, preventing unplanned downtime and reducing the need for emergency maintenance, Meid notes.

The system also generates detailed reports and analytics, providing insights for manufacturers on equipment performance and helping to identify areas for improvement.

Another advantage of DriveRadar is its ability to scale with a company’s requirements.

The services in SEW-EURODRIVE’s DriveRadar portfolio, therefore, provide operators with the tools they need to draw conclusions about the status of the equipment, wear and tear, and capacity use based on real data so that they can then derive recommended courses of action.

“This flexibility makes it an attractive solution for companies of all sizes.”

DriveRadar can also be used in conjunction with Smart System for energy management and optimisation.

Monitoring energy use in real time with Smart System enables manufacturers to identify areas where they can reduce consumption and optimise their operations. This not only reduces costs but also helps to minimise a company’s environmental footprint.

Under the umbrella of DriveRadar, SEW-EURODRIVE offers intelligent, scalable services for the smart factory along the entire life cycle of individual products and complex systems to significantly increase their availability.

As the IIoT continues to evolve, solutions such as DriveRadar will become increasingly important in helping manufacturers stay competitive in an ever-changing industrial landscape, Meid concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation