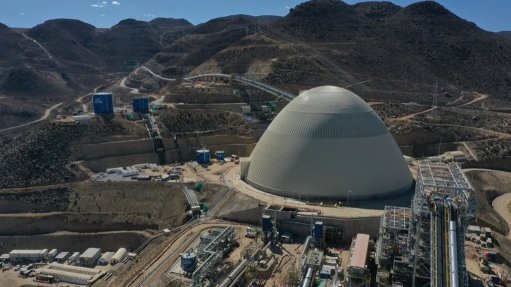

Colluli potash project, Eritrea

Name of the Project

Colluli potash project.

Location

The project is located in the Danakali Depression region of Eritrea.

Project Owner/s

The project is 100%-owned by the Colluli Mining Share Company (CMSC), a 50:50 joint venture between Danakali and the Eritrean National Mining Corporation (ENAMCO).

Project Description

In a front-end engineering design (FEED) study completed in January 2018, the Colluli project was established as the most advanced, economically attractive and fundable sulphate of potash (SoP) greenfield development project globally.

The project has a Joint Ore Reserves Committee- (Jorc-) compliant mineral resource estimated at 1.29-billion tonnes grading at 11% potassium oxide for 260-million tonnes of contained SoP equivalent.

The Jorc-compliant ore reserve is estimated at 1.1-billion tonnes grading at 10.5% potassium oxide for 203-million tonnes of contained SoP equivalent.

A modular development approach for the Colluli project has shown a highly scalable, long-life project. The shallow mineralisation of the project makes the resources amenable to opencut mining.

The mine will comprise one openpit developing progressively from north-east to south-west. The pit will have a progressive working face that will provide access to each of the mineralised layers simultaneously. The orebody comprises sylvinite, carnallitite and kainitite, which will be fed as ore feed into the processing plant and from which sylvite, carnallite and kainite will be extracted and mixed to produce SoP.

The project proposes two modules.

Module 1 is expected to produce 472 000 t/y of premium SoP.

Module 2, starting production in Year 6 of the project, will increase total SoP production to 944 000 t/y.

Mining will be conducted by mining contractors using conventional mechanised equipment, with no drill-and-blast required. Mined ore will be transported by truck to a run-of-mine pad adjacent to the processing plant.

The massive Colluli ore reserve has significant capacity to underpin further expansions and support decades of growth beyond modules 1 and 2.

Colluli has significant diversification potential beyond SoP, including the option to produce additional potash and salt products such as muriate of potash, SoP-magnesia, kieserite, gypsum, magnesium chloride and rock salt.

At FEED production rates, the project has an expected mine life of 200 years.

Potential Job Creation

The project could create more than 500 permanent jobs for locals and Eritrean nationals in Module 1, and more than 650 (cumulative) jobs once Module 2 is on line, and benefits from strong local support. During construction and the early stages of production, there will also be numerous jobs for expats.

Net Present Value/Internal Rate of Return

The project has an after-tax net present value, at a 10% discount rate, of $902-million for modules 1 and 2, and an internal rate of return of 29.9%. Module 1 has a payback of 3.25 years.

Capital Expenditure

Module 1 will require an initial capital investment of $302-million. The incremental Module 2 development is expected to require an initial capital investment of $202-million.

Planned Start /End Date

Production is expected to start in 2022.

Latest Developments

Danakali has made progress on Phase 1 of the Colluli project’s engineering, procurement and construction management contract.

The company envisions that Phase 2 will start in mid-February, which will be followed by geotechnical investigation works that will start in March.

Danakali has appointed consultancy DRA Global, and multinational professional services company Turner and Townsend to review the Colluli front-end engineering design, which includes developing project systems, project controls and progress measurement monitoring.

DRA has also started project management activities and mobilised its own engineering group for the process plant and associated infrastructure work. The consultancy has also undertaken a water intake area design for the Colluli project.

Key Contracts and Suppliers

Fluor (FEED engineering lead, metallurgy, process and nonprocess infrastructure, and capital and operating cost estimates); AMC Consultants (mine – geotechnical, mine design, mine contract tendering support, compilation of mining costs and competent persons report, and ore reserve update); Knights Piésold (evaporation ponds and tailings, infrastructure geotechnical investigations and hydrogeological investigation and modelling); Global Potash Solutions and Elemental Engineering (metallurgy and processing technical support); Ausenco (water abstraction and pipelines); Braemar ACM (port capacity, capability and handling fees, and engagement of shipping lines); MBS Environmental (social and environment); and Turner & Townsend (FEED review).

The company and project also have a strong network of partnerships, including EuroChem (offtake), DRA Global (EPCM contractor and FEED review), Inglett & Stubbs (power contractor), Africa Finance Corporation or AFC (debt financier) and the Africa Export-Import Bank, or Afreximbank (debt financier).

On Budget and on Time?

Not relevant at this stage.

Contact Details for Project Information

Danakali, tel +61 8 6315 1444, fax +61 8 9467 9119 or email info@danakali.com.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation