Booyco expands its coal footprint as Level 9 looms

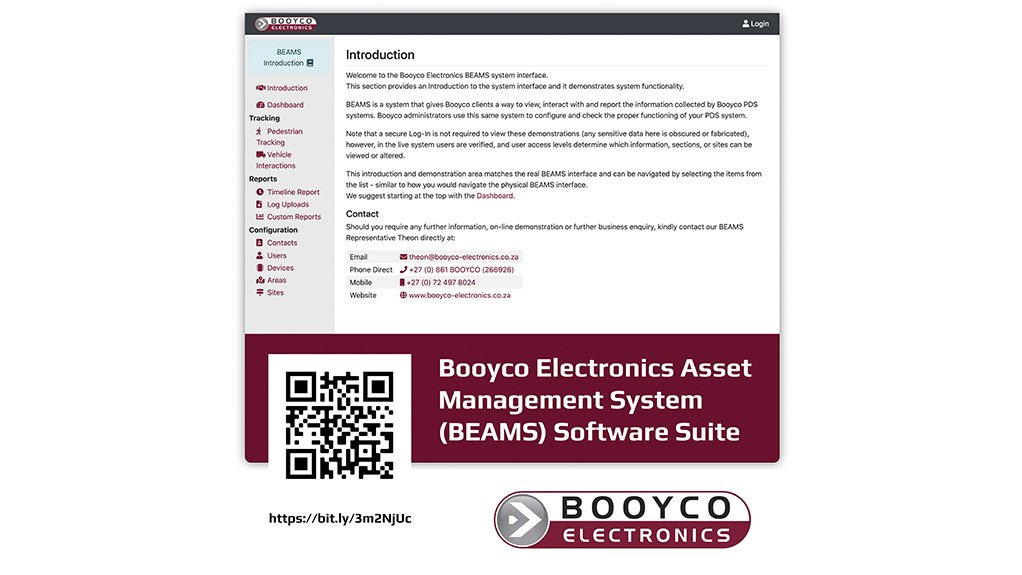

Another contribution to safety and productivity is the Booyco Electronics Asset Management System (BEAMS) – a central information hub for a mine’s PDS assets

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Coal mines were among the first customers of proximity detection system (PDS) specialist Booyco Electronics, and the company continues to grow its footprint in this sector as mines work towards Level 9 compliance.

According to Booyco Electronics CEO Anton Lourens, the scale of recent orders from underground collieries and opencast operations are testament to the company’s leadership in the sector.

“We support an extensive population of our proximity detection equipment on trackless mining machines (TMMs) in coal mines, and expect to see enthusiastic take-up of our new-generation Booyco CXS product,” says Lourens. He highlights that the customer base includes not only the Mpumalanga coalfields, but also those in KwaZulu-Natal province – supported by the company’s network of branches including Witbank and Richards Bay.

Regulations currently demand that any electrically powered TMM in an underground mine must be equipped with a PDS, but many coal operations have a combination of diesel and electric units. He emphasises that the regulatory framework will soon enforce Level 9 requirements – with more advanced collision avoidance capability – for both diesel and electric TMMs.

“We are working closely with many OEMs and mining customers on aligning and testing our respective equipment for Level 9 compliance,” he says. “It should be remembered, however, that the industry still has considerable work to do on the application of PDS technology to surface diesel TMMs, which pose a range of technical challenges.”

An active participant in the mining industry’s Earth Moving Equipment Safety Round Table (EMESRT), Booyco Electronics collaborates extensively with stakeholders to support mines’ safety and compliance efforts.

“Coal mines have a key role to play in the testing and application of collision avoidance systems, as the industry upgrades to ever-more effective safety protocols,” says Lourens. “The Booyco CXS consolidates all we have learnt in our 15 years in business, taking that vital step from a warning system to a fully-fledged collision avoidance system.”

He highlights that the Booyco CXS retains the intrinsically safe technology of previous generations, making it more cost effective and generally easier to manage. “The common alternative to intrinsically safe equipment is for suppliers to add a flameproof enclosure to house the PDS, which tends to be heavy and impractical,” he says.

Another contribution to safety and productivity is the Booyco Electronics Asset Management System (BEAMS) – a central information hub for a mine’s PDS assets. Centralising information from PDS hardware and monitoring devices, BEAMS enhances operations by identifying patterns of unsafe behaviour that can be promptly addressed.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation