BBE brings cooling to Mali mine

Company Announcement - BBE Projects has been awarded a mine cooling project for the complete turnkey design and build of two refrigeration and air-cooling installations in Mali. This is BBE Project’s third refrigeration installation this year in Africa, the first being the second phase of the air-cooling programme at Acacia Mining’s Bulyanhulu Gold Mine in Tanzania, comprising two 3.5 MWr York ammonia screw compressor refrigeration machines producing chilled water for a surface bulk air-cooling tower straddling a 1 000 m deep dedicated ventilation hole for the west section of the mine. The second installation is an underground plant comprising three Trane 1.5 MWr three-stage centrifugal refrigeration machines providing chilled water through a closed-circuit network of cooling cars at a depth of almost 3 000 m at Sibanye’s Driefontein Gold Mine.

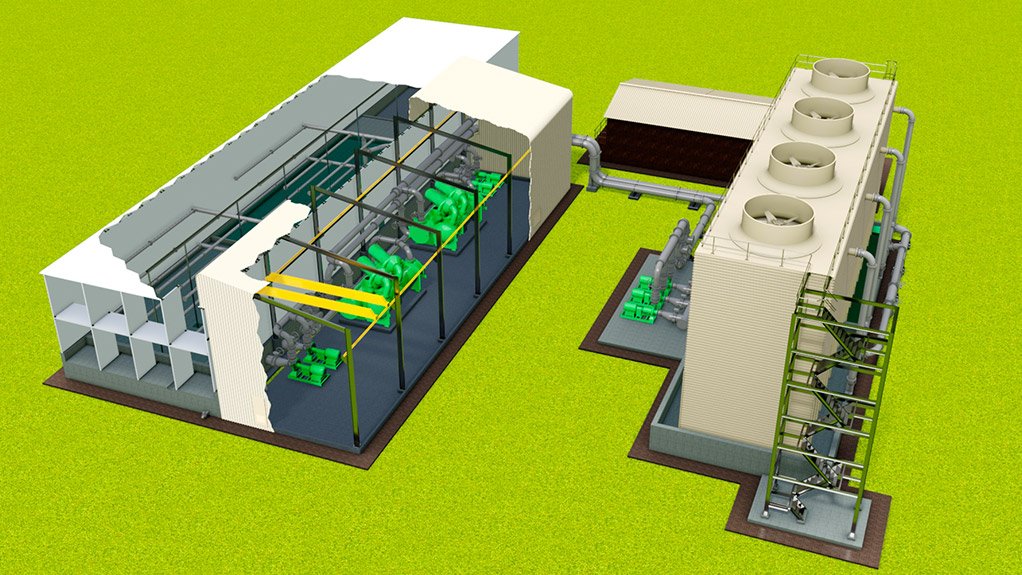

The mine cooling project in Mali is for coolers that will be located on surface at the top of two new dedicated downcast ventilation holes at a gold mine. The coolers will each provide more than 14 MWr of air-conditioning for the deeper levels of the underground workings. Each installation will comprise two 7 MWr dual-compressor York YD R134a refrigeration machines producing chilled water for a horizontal spray chamber.

“A particular feature of these installations is that the air will be drawn through the ventilation holes by underground fans, so that the surface air coolers will be under a slight negative pressure from the induced ventilation,” says Richard Gundersen, Managing Director of BBE Projects. “This has allowed the selection of lightweight building materials for the shell of the air coolers which offers savings in terms of cost and also speed of erection. Likewise, the condenser cooling towers for heat rejection will be constructed from lightweight FRP components with similar cost and time benefits.”

The shell of the bulk air cooler will be assembled from 1200 mm wide steel-clad insulated panels fitting together in a tongue-and-groove manner, coupled with a light aluminium structure and attached directly alongside the main plant room. The use of this material and the resulting compact layout also contribute to a high thermal efficiency as the chilled water from the refrigeration machine is sprayed directly into the intake air stream, with no losses from interconnecting pipework. The entire plant occupies a footprint of just fifty square metres.

With all power for the mine coming from on-site generators, Gundersen says that special attention has been paid to overall system efficiency and low power consumption of the cooling system. “This affects several design parameters such as the number of tubes in the heat exchangers, water flowrates in the two circuits and the size (and therefore thermal approach) of the condenser cooling towers. The generators have also required careful consideration of electrical start-up demands and the selection of the dual compressor machines has halved the maximum instantaneous start-up current. Nevertheless, starting the plant will require a handshake protocol with the power station to acknowledge and prepare for the build-up of an additional 3 MW electrical load onto the system,” says Gundersen.

The remoteness of the location has necessitated that the cooling system be designed to be simple to operate with a minimum of control elements. Consequently, there is only one temperature-controlled valve on the water circuits in the entire plant and load control of the compressors is achieved with conventional inlet guide vanes.

Being vital to mining operations, the specifications place particular emphasis on overall system availability which has been designed with generous modularity and is well-equipped with stand-by equipment and components. All water circuits have permanently installed stand-by pumps.

Gundersen says that civil construction activities have already started at the first of the two sites and the first plant will be operational by mid-2016. The construction and commissioning of the second plant runs in parallel to the first plant with a stagger of about two months.

The supply of components comes from around the world and the logistics amount to some seventy-five containers and flat racks from the USA, Brazil, India, Malaysia and Europe with the majority from South Africa. The routing is to the port of Dakar followed by 800 km of overland transport to the mine. In line with most mining companies’ localisation programmes, BBE Projects will engage local contractors for the on-site construction, erection and installation works.

BBE Projects delivers tailor-made ventilation, refrigeration and air cooling installations in a single turn-key package, with an enviable record of successful projects completed across the African continent over the past 12 years, including in South Africa, Ghana, Tanzania and Zambia. BBE Projects is a member of the BBE Group which has been providing a comprehensive worldwide consulting service specialising in mine ventilation, refrigeration, air-cooling and energy for all mines in all climates for over 25 years.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation