Arcadia lithium project, Zimbabwe – update

Name of the Project

Arcadia lithium project.

Location

Outside Harare, in Zimbabwe.

Project Owner/s

Prospect Resources (87%).

Project Description

An updated definitive feasibility study (DFS) on Arcadia, released in December 2019, confirmed the project’s strong financial and geological merits, positioning the company to be a leading producer of lithium and battery minerals.

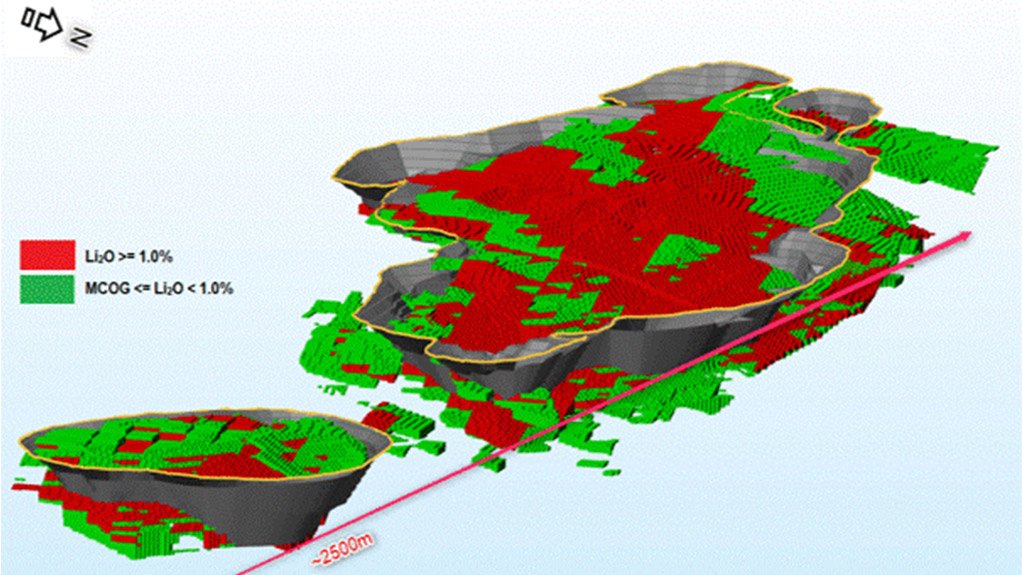

The project’s total proven and probable reserves have increased from 26.9-million tonnes grading 1.31% lithium oxide and 128 parts per million (ppm) tantalum pentoxide in the 2018 DFS to 37.4-million tonnes grading 1.22% lithium oxide and 121 ppm tantalum pentoxide in the updated 2019 DFS.

The updated DFS envisages a 2.4-million-tonne-a-year conventional openpit mining operation, producing average concentrate of about 173 000 t/y of 6% spodumene, 24 000 t/y of chemical grade petalite and 98 000 t/y technical grade petalite at a concentrate grade of 4%, as well as 174 000 lb/y of tantalum at a concentrate grade of 25%. Mineral processing will be based on using conventional beneficiation techniques, including the gravity-based processes of dense-medium separation and spirals, to recover petalite and tantalite. Froth flotation will be used to recover spodumene.

Process tailings will be disposed of at an engineered tailings storage facility (TSF).

The project’s mine life has been extended from 12 years to 15.5 years.

Potential Job Creation

Not stated.

Net Present Value/Internal Rate of Return

The project’s pretax net present value has increased from $511-million, at a 10% discount rate in the 2018 DFS, to $710-million in the updated 2019 DFS.

The pretax internal rate of return has increased from 44% in the 2018 DFS, with a payback of 2.5 years, to 71%, with a payback of 18 months in the updated 2019 DFS.

Capital Expenditure

The preproduction capital cost of the project has decreased from $165.2-million in the 2018 DFS to $162.4-million in the updated 2019 DFS.

Planned Start/End Date

The ground-breaking ceremony for the project was held in November 2018.

The project is expected to be completed in the third quarter of 2020, with commissioning from November 2020.

Latest Developments

Prospect Resources has completed 92% of the work on its engineering, procurement and construction scope for the Arcadia project.

Some of the milestones completed for the plant include flowsheet and detailed engineering, procurement of equipment, power supply connection and reticulation on site, ore stockpile prepared to feed crushing circuit, and earth- and civil works.

Prospect has said that production and first shipment of petalite product will start by the end of June.

Prospect MD Sam Hosack has said that the company is “shovel ready” to develop the Arcadia project.

Key Contracts, Suppliers and Consultants

Roger Tyler (resource definition); ADP Marine & Modular (DFS – process design review, final engineering cost estimate, health, safety and environment management plan, project execution plan and quality management plan); DRA Global (process design); Gayle Hanssen (resource modelling); Adam Moodley (project geologist); Practara (geotechnical services); David Miller (mine planning and minerals marketing); Envirosmart (environmental-impact assessment); Constant Chuma (hydrogeological assessment); Mike Kitney (metallurgy); Blonton Management (TSF design); Norconsult (electrical network analysis); JJ Transport (transport fleet study); Lee John (consultant metallurgist); Trevor Barnard (project manager) and Iain Sheasby (project modelling).

Contact Details for Project Information

Prospect Resources, tel +61 8 9217 3300 or email info@prospectresources.com.au.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation