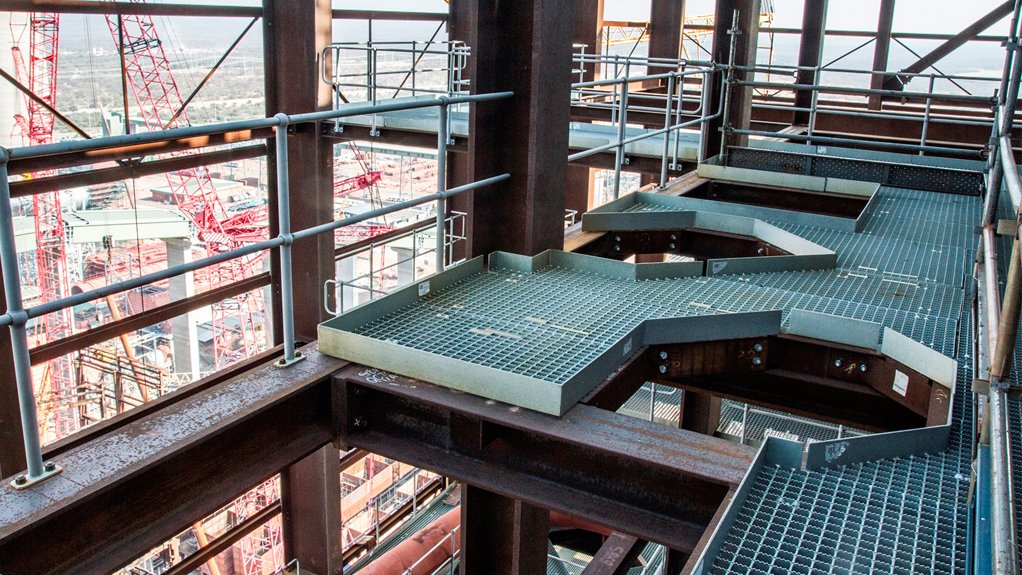

Africa’s largest gratings, handrail and stair tread contract successfully completed

MEDUPI GRATING Vital Engineering has delivered 200 000 m2 of a high-performance, quality grating and handrailing product ahead of schedule at Eskom’s Medupi and Kusile power stations

Vital Engineering, a company dedicated to ensuring optimum human resource safety on site, has been closely involved in power utility Eskom’s coal-fired power generation projects, Medupi and Kusile.

An established manufacturer of safety handrails, floor gratings and expanded metals, the company supplied bespoke components to both plants. This included 100 000 m2 of grating panels per power station, as well as about 70 km of handrailing and over 8 000 stair treads.

Vital Engineering MD Dodds Pringle says the project represents the largest gratings, handrail and stair tread supply contract to be undertaken in Africa.

“We are extremely pleased that Vital was well ahead of schedule in meeting our capacity guarantees for both power stations. In addition, we are proud to have reported a 0 – 0001% non-conformance report (NCR) on both plants, out of a total supply package of over 8 000 t of product. This related to revisions after the products were already delivered on site. This commendably low NCR rate, I believe, is testament to Vital’s high manufacturing standards, our total quality management (TQM) philosophy and strict adherence to systems management,” says Pringle.

Founded in 1939, Vital Engineering has built a reputation for its uncompromising attitude towards quality in the industries it serves, including petrochemical plants, materials handling projects, mining, power generation, process plants and food and beverages, as well as civil and structural engineering. The company’s range of non-slip walkways, stair treads and safety handrails are manufactured using a variety of materials to match design specifications, including galvanised steel, stainless steel, fibreglass and aluminium.

Vital Engineering also has extensive experience in the supply of components to power stations locally and internationally. These include combined cycle gas, nuclear, hydro and fossil-fired stations in South Africa, Hong Kong, China, Turkey, South America and more recently in the rest of Africa.

The high grade 350 WA steel used for the Medupi and Kusile projects had to conform to stringent Eskom specifications, as well as project contractor specifications, in this case Mitsubishi Hitachi Power Systems Africa. To further ensure the highest quality possible, various tests and procedures, including load testing and welding grade testing, were undertaken by Vital Engineering.

“A high-strength and -quality, hard-wearing product has long-term cost saving implications for the client because maintenance cycles are significantly reduced. More critical, however, is the performance of this product, which ensures a high level of worker safety on site,” notes Pringle.

“Most suppliers feel that eliminating lost time injuries is the responsibility of the erector or contractor,” he argues. “At Vital we see safety as our top priority, ensuring not only that our products conform to the design specifications of the client but that they are manufactured with the highest grade material.”

Going the extra mile is part of Vital’s modus operandi, and it offers a number of back office value-adds that the company sees as being part of the normal course of business, to ensure client satisfaction.

“To ensure proper fitment on site, we undertake full pretrial layouts of flooring before the product is released to site. This serves to minimise any downtime or installation delays,” says Pringle.

“Vital is proud to have delivered 200 000 m2 of a high-performance, high-quality product - with minimal NCRs - ahead of schedule for Eskom’s new power generation plants. Our extensive experience, high-grade materials and qualified welders have all contributed towards a successful project completion,” Pringle concludes.

Hall 6 Stand F17

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation