Energy efficient beneficiation

ZUNAID MOTI The new smelting plant represents African Chrome Field’s first venture into mineral beneficiation in keeping with Zimbabwe’s growing emphasis on local mineral processing

ZIMBABWE FOCUSED African Chrome Fields has invested $250-million into operations in Zimbabwe

LONG TERM African Chrome Fields estimates that its Zimbabwe mine will have a life of at least 20 years, with a possibility of extension to up to 40 years

An R800-million mineral beneficiation plant in Zimbabwe has been unveiled by Zimbabwe-based chrome producer African Chrome Fields, which uses a modern aluminothermic process that is energy efficient.

The technology is the culmination of several years of research and testing, and was specifically developed in response to a lack of available power and infrastructure in Zimbabwe, states African Chrome Fields chairperson and country representative Zunaid Moti.

“The Zimbabwean government has placed increasing focus over the years on beneficiating its natural resources and minerals as opposed to exporting raw material with the aim of promoting inclusive, sustainable economic growth. In line with this thinking, we took the decision to build a plant to beneficiate our chrome within the country.

“Over the past few years, we have invested more than R1.2-billion to develop completely new technology that is not dependent on electricity.”

At present, African Chrome Fields has an investment of $250-million in Zimbabwe.

Unlike traditional power- and carbon-intensive furnaces, the aluminothermic plant draws on a proprietary chemical mixture to produce the heat needed to convert raw chrome ore into ferrochrome – a specialised ferroalloy used in stainless steel manufacturing.

This proprietary mix ensures that the ferrochrome produced is ultralow carbon, high-grade ferrochrome featuring between 62% and 65% chromium and just 0.2% carbon.

“To explain the process, we take atomised aluminium and chrome concentrate, [and] mix it with other accelerants. The mix then self-ignites and the aluminothermic process takes over, producing a very hot chemical reaction that is completed within a few minutes rather than the hours needed to produce the same reaction in furnaces.

“The slag then separates from the ferrochrome, and once the mix has cooled, we can remove the ferrochrome, which remains of exceptionally high quality without harmful contaminants,” he says.

As a result, the ferrochrome produced is suitable for specialised high-grade stainless steel manufacturing for end clients in the aeronautics and construction industries, among others.

Headquartered in South Africa, African Chrome Fields is a private, black-owned mining company with mining operations spanning along the Great Dyke region in the Midlands province of Zimbabwe.

The new smelting plant represents the company’s first venture into mineral beneficiation in keeping with Zimbabwe’s growing emphasis on local mineral processing.

Alluvial Mining

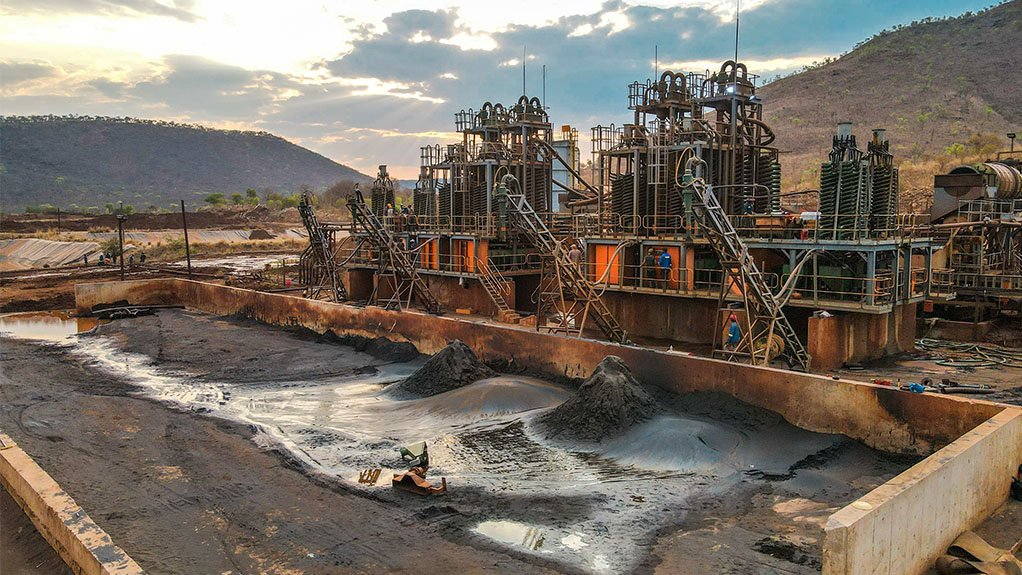

In addition to its aluminothermic technology, the company boasts extensive alluvial mining operations in the area, drawing on the upper layers of soil between 1 m and 3 m deep to extract chrome.

African Chrome Fields currently has seven wash plants, the latest of which is a double plant that has increased its chrome production to 550 t a day, or 20 000 t a month.

These wash plants rely on a simple combination of water and gravity to separate sand from the chrome ore. Once production at Plant 6 starts – expected within the next 90 days – production will increase to 30 000 t/m.

The company has invested $250-million into expanding its mining operations since 2014, including the construction of necessary infrastructure such as boreholes, roads and accommodation for staff, as well as the construction of seven wash plants.

Likewise, its staff component has grown from less than 40 individuals to over 600 employees, contributing significantly to job creation and economic development in the region.

The life of the mine is expected to endure for at least 20 years, and can be extended by up to 40 years, claims African Chrome Fields, as a result of the richness of the chrome reserves in the area.

This, Moti says, will provide long-term job security for local employees and hope for further sustainable socioeconomic development and stimulus for decades to come.

“The investment made by African Chrome Fields has not only brought technological advancement but has also contributed significantly to employment opportunities, skills development and infrastructure enhancement in Zimbabwe.

“Through the power of public-private partnerships, we have witnessed the transformation of natural resources into sources of sustainable prosperity.

“As we continue our progress, Zimbabwe as a country is likewise forging forward. “We strongly believe that the future for African Chrome Fields and for Zimbabwe is bright, and we hope to continue fostering a deeper understanding of our efforts as we work to reimagine the future of Zimbabwe and of mining,” he concludes.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation