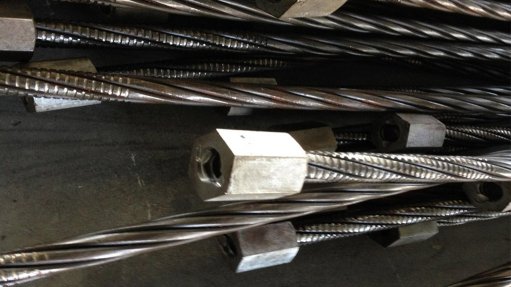

BRACE YOURSELF The Flexibolt is used in mines at the stope to brace the surface for a safer mining environment

The shift towards mechanisation in the mining industry has prompted cable anchor supplier M and J Mining to continue developing and enhancing its Flexibolt range of prestressed cable anchor solutions and other technologies necessary to support the ever-changing needs of the deep-level mining industry.

“Our Flexibolts are constantly evolving as we push the boundaries of underground support,” says M and J Mining sales director Daniel Mathews.

The Flexibolt – essentially a threaded cable anchor – is a relatively new product that is patented under South African law. The Flexibolt has its threads cut directly into the cable diameter and provides an ultimate tensile strength close to 80% of the cable.

The application of a thread at the end of a Flexibolt support product enables a mine to install longer flexible support in “high-risk areas” without having to involve secondary support crews. The resulting product has created a niche support area, which has evolved into what is now known as a single support pass, Mathews explains.

The flexibility of the Flexibolt enables a designer on site to create a more effective support system that anchors itself higher into the hanging wall of the stope than the narrow stope height would allow if a solid steel roof bolt were used.

“Faith in this new technology has increased over the past few months and we have been supplying Flexibolt solutions to more mines as the product is proving itself,” Mathews enthuses.

M and J Mining has also identified the growing need for yielding support in deep-level gold mines, owing to seismic activity. After investigating various systems, the company can supply dynamic bolt reinforcement systems – comprising Garford bolts – to the local market. The bolts are manufactured under licence by roof support system manufacturer Videx Mining.

“We now supply the mines’ primary support requirements and are constantly monitoring the underground performance of our product to customise it to the ground conditions in that mine.”

Videx Mining purpose-built a dynamic drop test facility at its manufacturing plant in Germiston, Gauteng, to ensure quality control on every batch of products delivered.

“This facility affords M and J Mining the opportunity to develop similar yield-based support solutions, which will satisfy further needs within seismically active, deep-level mines in South Africa and Southern Africa,” he says.

The company has taken up new technology not only in its manufacturing but also in its after-sales services, with a new website and point of contact for clients. “Embracing technology helps us to keep up with the latest developments in line with the marketplace that is constantly changing,” he adds.

M and J Mining specialises in cable support solutions, which enables it to provide customised solutions for deep-level mines and other underground operations. If these solutions are not immediately available, the company can engineer a customised support solution for existing and future clients.

“By working with clients, our support solutions provide a cost-effective support solution so that mines can extract value from difficult ground conditions safely,” says Mathews.

“M and J Mining plans to further entrench the advantages of its stope anchors, such as the Flexibolt, in more shafts and other mining houses in the future,” he concludes.