Problems in tailings dams can cause catastrophic repercussions on active mines and incur massive failure costs and safety hazards.

With common failures being caused by leaks, seepage, and poor maintenance of dams, drones meet a vital operational need when it comes to reliably monitoring dam issues on a regular basis.

Here is all you need to know about how Rocketmine’s drone thermal leak detection solution provides a safe, speedy and inexpensive way to address the common problems active mines face when it comes to tailings dam management:

Traditional Tailings Dam Inspections Versus Drone Deployment

Currently, tailings dam inspections are carried out on foot. These inspections are labour intensive, involve a moisture meter, trial pits and geotechnical equipment to physically measure saturation levels in the soil.

Moreover, these manual solutions are slow, expensive, difficult, and limited to safely accessible areas of the dam.

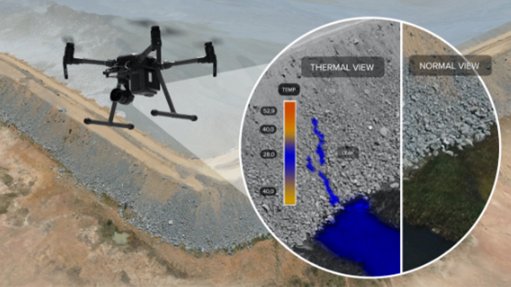

However, with Rocketmine’s drone thermal leak detection solution one can easily detect temperature differences within tailings dam walls. This allows moisture, wet areas and potential seepage to be identified that would have been missed by the naked eye.

We fly the entire dam area; keeping your staff out of harm’s way and helping you quickly and safely pinpoint the exact, geo-referenced areas where leakage has occurred.

This allows you to plan more effectively and attend to urgent issues immediately.

Additionally, we deploy drones with standard RGB cameras which enables us to identify whether there any structural defects present such as bulging or pressure in the wall which could cause a catastrophic blow out of a section of the tailings dam.

Instead of replacing the entire dam wall, our thermal drone imagery allows you to target the exact areas needing repair, enhancing tailings dam management, improving productivity and saving you time and money.

After inspection flights have been conducted, drone imagery is then handed over to mine engineers for accurate analysis.

This data is then used to compile mandatory quarterly reports on the integrity, quality and structural stability of tailings dams, serving as empirical evidence of legal compliance to the Department of Mineral Resources.

Furthermore, with drone imagery being collected every quarter (or at a greater frequency such as monthly, weekly or daily), thermal data collected from multiple flights can be overlaid to create a trend analysis.

This will help to detect changes in the shape and size of the dam, pick up issues that were not previously identified and determine the growth rate of these issues over time - which would ordinarily go unnoticed.

This in turn will allow you to accurately predict tailings dam failures and effectively plan mitigation work.

The Final Word

By employing drones with thermal leak detection capabilities, active mines are able detect temperature differences, identify moisture leakage and recognise surface movements in tailings dams.

This helps to precisely detect potential issues prior to occurrence, prevent disastrous events, keep staff safe, remain legally compliant and save on failure costs.

Drones can therefore be considered an integral operational resource and can be confidently relied on when it comes to the effective monitoring and management of on-site tailings dams.