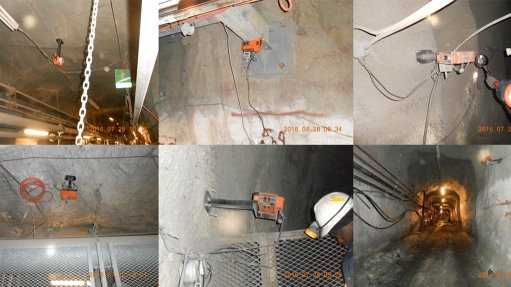

CLEARING THE AIR The Vuma-network of technologies is being offered free of charge to the mining sector to help ensure that ventilation post care and maintenance is up to scratch

Mine ventilation, refrigeration, and cooling engineering consultants BBE Group, in August released the 2021 version of its flagship Vuma-network, free of charge, to the mining sector and other interested parties worldwide.

BBE’s in-house product, called Vuma-transient, used by BBE engineers, enables a mine to estimate its recovery time following a period of nonoperation, typically following a power or mechanical failure of the ventilation appliance.

However, it can also be used for prolonged periods of inactivity, such as care and maintenance.

“Vuma-transient can be applied to care-and-maintenance shafts as the mine progresses in its build-up to full production. In this instance, it can be used to estimate the timing of the systems’ recovery, as well as the correct combination of airflow and cooling required,” says BBE Consulting ventilation engineer Miguel Coelho.

He adds that the free offering of the technology underpins BBE’s mission and vision to ensure the health and safety of mineworkers underground.

BBE notes that, while the solution was developed within a South African context, the platform has been adapted to cater for various languages, including Chinese, Polish and Spanish.

It can incorporate the integration of country-specific features, design criteria and well-known mining and engineering solutions. It is also aligned with international industry standards.

Coelho points out that the software is vendor-agnostic and will integrate with all major industry software and solution providers. He reiterates that users are not required to be associated with BBE to use the new software.

Vuma Software CTO Hendrik Botma tells Mining Weekly that the new 64-bit version of the former network and mine ventilation simulation tool have been offered to existing, former and potential clients.

“With the advanced simulation technology, mining and ventilation engineers can gain complete control of the ‘critical over the crucial’ ventilation and cooling aspects of mining processes across a range of mining methods.”

Botma adds that mine planning software is becoming increasingly sophisticated, and that the type of graphic ventilation network detail and troubleshooting that Vuma-network can provide is becoming “invaluable”.

Vuma products are not currently geared to predict when ventilation maintenance is required, but the concept is being researched by BBE, says Botma.

Currently, with Vuma-live, a mine can predict underground environmental conditions such as temperature and airflow, which can provide the mine with insight into ventilation conditions.

The rationale for releasing the Vuma-network free of charge is as a result of BBE’s vested interest in ensuring safer mining operations; this desire is underpinned by BBE engineers continuously developing Vuma software to create safer environments.