HIGH TECH Operators no longer have to leave the cab or interrupt the ongoing process and they can detect on the smartphone that the diesel fill level is low

The innovative digital operating concept SPECTIVE from crushing plant producer Kleemann, supplied by German construction company Wirtgen Group, has optimised the control options of crushing plants in a “trendsetting manner”.

With the SPECTIVE CONNECT extension, Kleemann goes one step further. All relevant process information and reporting can now be displayed on the smartphone without having to leave the feeding device.

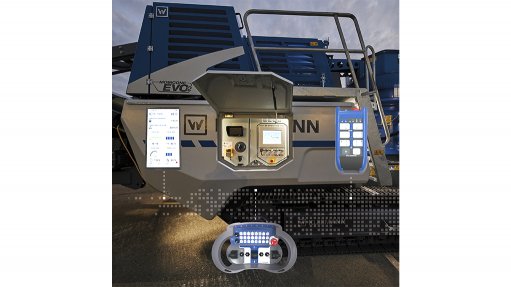

With top technologies to a higher performance and with its SPECTIVE operating concept, Kleemann is the sector leader in terms of user interfaces. The plant is started through the 12” SPECTIVE touch panel directly at the plant. The intuitive operating concept makes it easy for users to make the necessary settings.

Once it has been set, the plant runs in automatic mode. When a plant train is used, after initial setup the operator can connect to the complete plant train and with each individual plant. As a new feature in the SPECTIVE world, the radio remote controls have been integrated. Using the large radio remote control, the plants are moved from the low loader and the setup procedure can be carried out conveniently and at a safe distance from the machine. The small radio remote can be used to execute all relevant functions comfortably from the excavator.

SPECTIVE CONNECT is the plant control application “with real added value”. Diesel fill level, average fuel consumption, average plant performance, gap setting, use rate and other important process data can be displayed at any time on the dashboard.

In most cases, operators no longer have to leave the cab or interrupt the ongoing process. They can detect on the smartphone that the diesel fill level is low and order fresh supplies directly from the driver’s cab.

Operators can see the machine use rate at a glance and can regulate loading. They can also receive data on the daily output already achieved and also compare it to the previous day.

SPECTIVE CONNECT also provides enhanced safety for the operator, higher plant availability, higher use and, consequently, better cost-effectiveness.

In future, the operator can obtain a plant overview of the infeed and the complete crushing plant through the camera system on the smartphone display. In case of a malfunction, SPECTIVE CONNECT displays both the general fault and, simultaneously, the corresponding components including troubleshooting aids. The smartphone can be taken to the location of the fault to support the operator in step-by-step fault elimination.

The SPECTIVE CONNECT application automatically generates clearly arranged reports on consumption and plant performance as well as the plant use. These reports can be forwarded by messenger or email. This guarantees transparency in the complete process.

SPECTIVE CONNECT is currently available as an option for the new jaw crushing plant MOBICAT MC 110(i) EVO2 and the new cone crushing plant MOBICONE MCO 90(i) EVO2. Further, SPECTIVE machines will be equipped or retrofitted with this option gradually. The application can be installed on iOS and Android smartphones.