SKF West Africa identified a number of lubrication issues while conducting a paid lubrication audit for a long-standing mining customer in the Republic of Guinea. “Our objective with the audit process was to gain a better understanding of our customer’s existing lubrication and maintenance strategy, their lubricant purchasing and Automatic Lubrication System (ALS) management process as well as their environment protection plan,” explains , Lubrication and CoMo Champion for SKF West Africa, Ouattara Yelli Fatou.

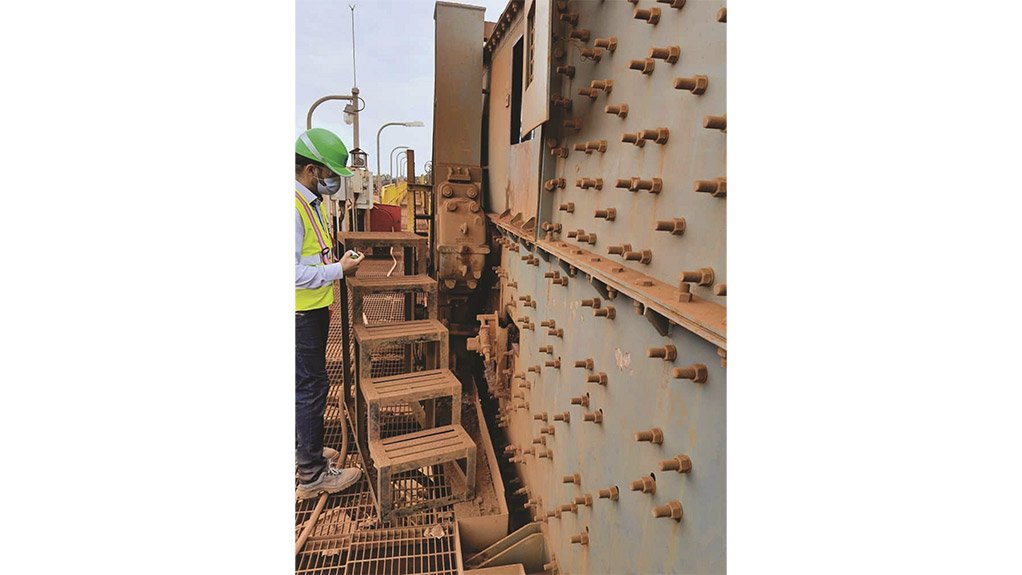

The comprehensive audit done by Hassan Missaoui and Yelli Ouattara was conducted on lubrication management as well as on all lubrication products including lubricant and tools. “We also looked at the mine’s maintenance and condition monitoring (COMO) products and strategies,” affirms Fatou. “In addition to the failure of large slew bearings, gearbox oil was overheating. We also noticed a lack of equipment monitoring devices and recognised that our customer needed assistance with lubrication management in terms of best practices and skills.”

The all-inclusive lubrication solution proposed by SKF included an oil storage room, twelve oil conditioning units (OCUs) and 200 System 24 TLSD series lubricators. According to Fatou the oil storage room will improve oil storage, conditioning, dispersing and oil cleanness levels. The OCUs will help to cool and filter gearbox oil to prevent overheating.