Drive and control technologies specialist SEW-EURODRIVE has a wide range of products that are suitable for the mining industry, with some having been improved in recent years to most adequately suit a harsh mining environment.

The German drive technology manufacturer is rolling out its X.e Series product range on a larger scale in South Africa in 2021, with increasing exposure in 2022, when the company’s new head office will be completed.

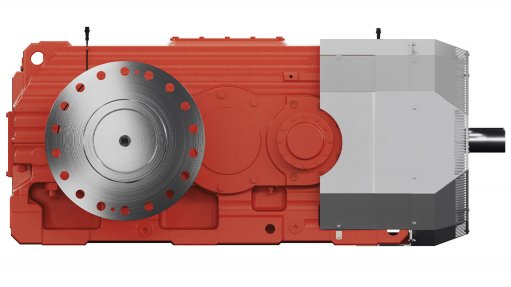

The X.e Series forms part of the company’s industrial gear portfolio and offers durability, finely graduated sizes, and an invertible housing as the main characteristics of its tried-and-tested X-Series industrial gear units.

“These industrial gear units can be adapted individually and precisely to the respective requirements of a client’s particular application in terms of operation and the surroundings,” explains SEW-EURODRIVE national sales and marketing manager Jonathan McKey.

This offers the highest possible efficiency, exceptional safety and a long service life, even in harsh conditions, he says.

McKey explains how important technology is in the innovation of products: “It improves efficiency in line with the latest global trends, it lowers the impact on the environment, it saves costs and ensures that our products are current for today’s exacting standards”.

Technological advances in the X.e Series industrial gear units include contactless sealing systems, which provides significantly longer maintenance intervals; a reduction in the oil bath temperature, resulting in increased cost savings; optimised bearing preload, which significantly increases the bearing service life; an optimised gearing topology, resulting in a decrease in displacements and, therefore, no downtime; an improved bevel pinion housing that allows for optimised oil flow; and a universal fan guard that allows for optimal cooling within given sound pressure limits.

SEW-EURODRIVE also supplies segmented girth gears (SGG), which are used to drive large, rotating systems. SEW-EURODRIVE’s flexible concept has simplified manufacturing, transport and assembly, and the company aims to develop this product range further in future.

In addition to the SGG range, the manufacturer also offers planetary gear units, specifically the new PPK series, which is ideally suited to all heavy-duty applications that require a robust design, high gear ratios and compact dimensions.

The planetary gear unit product range boasts a wide torque and gear ratio range, making it the ideal solution for a variety of industrial applications that require durability and space efficiency. These products can be easily combined with SEW’s modular motor system to provide powerful support.

The specific benefits of the PPK series make it possible to use these units in a wide variety of industries and applications, including the mining, sugar and cement industry.

A standard geared motor range is also on offer and includes specialised condition monitoring.

Bell-housing

The company recently announced an update on its locally manufactured bell-housing solution, which uses more SEW original equipment manufactured cooling components, and an improved air flow over all components. It has also been refined for underground relocation and installation, offering a robust, compact solution.

The bell-housing was also designed to accommodate larger motors of up to 400 kW and, to ensure that sufficient cooling is provided, the new design accommodates an axial fan to ensure that the gearbox operates at lower temperatures, thus increasing the life of the oil.

The fixed design is achieved through a solid flange structure between the motor and the gearbox, with machined locating points for the gearbox and the motor. The skid enables the gearbox to be dragged underground to the installation point.

“This means that it will not require any realignment even after transportation and installation,” notes McKey.

The bell-housing design is used successfully in areas that are difficult to access, such as underground coal mining.

With normal swing base designs, it is possible for the alignment between the gearbox and motor to shift during transport, requiring that the unit be inspected again once it has been installed.

The SEW bell-housing design, however, ensures that the gearbox and motor shafts are always correctly aligned. Components can be changed at any time during the life of the product, and it affords easy access, installation and commissioning without alignment concerns.

“The bell-housing is designed and manufactured in South Africa and can be modified and adjusted to the customers’ requirements. This enables the customer to exercise greater flexibility for new and replacement drives,” explains McKey.

South African Headquarters

SEW-EURODRIVE’s South African headquarters services 23 African countries.

McKey states that client expectations regarding technology is crucial, as “they require reliable, modern, long-lasting products that have a strong aftersales service.”

This has consequently led to the construction of a new facility that will serve as SEW-EURODRIVE’s factory and new South African headquarters.”

It includes the construction of a 25 000 m2 factory, in Aeroton, Johannesburg, in Gauteng, on property acquired by SEW-EURODRIVE in 2018. The necessary earthworks were completed in October 2020.

The new factory will accommodate several of the company’s assembly plants in the country to develop better efficiencies and contain costs, as well as increased stock holding capacity.

Over a three- to five-year period, the factory will be fitted with Industry 4.0-compliant technologies, including automated assembly machines and guided vehicles.

The old head office and factory, in Aeroton, will become the company’s large-gearbox repair and servicing centre.

SEW-EURODRIVE diversifies not only its product range but also the way in which it conducts business within its own corporate environment, McKey notes.

“SEW-EURODRIVE has merged its export division with its sales and business development division, which enabled the company to stay closely connected to decision-makers and end-users,” he says.

The company is also increasing its investment on the African continent by employing additional support staff and growing its African footprint.

As one of the largest mechanical power transmission investors on the continent, SEW-EURODRIVE is confident in its ability to serve Africa’s mining industries through a large stockholding capacity and large staff complement to tackle all service and repair requirements, he concludes.