CLDP SERVO DRIVE Voith Turbo's new servo drive helps mitigate energy costs

Power-transmission specialist Voith Turbo’s new closed loop differential pump (CLDP) servodrive enables customers to mitigate rising energy costs caused by interrupted power supply as a result of load-shedding.

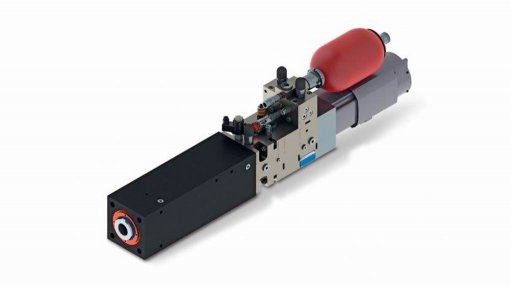

Voith Europe, Middle East and Africa division VP Grant Robinson says the design is simple and that flow rate is perfectly matched to the cylinder surfaces of a differential cylinder. He notes that the core is an integrated servopump consisting of a servomotor and an internal gear pump.

The unit also includes intelligent control through a fieldbus connection, a pressure limiter and a small compensating tank. This control system design renders other components, such as expensive valve engineering, unnecessary.

Robinson states that energy losses caused by throttle effects do not occur with the CLDP, increasing the machine’s energy savings by up to 50%, compared with machinery using conventional drive systems.

Meanwhile, the pump’s self-contained linear drive combines electromechanical and hydraulic systems, making it compact, dynamic and energy efficient. Additional benefits include overload protection, a high power density and virtually wear-free operation.

Robinson explains that the servodrive is essentially a hydraulic gearbox with an almost unlimited gear ratio, consequently making it ideally suited in applications with high dynamic speed requirements and high power demands.

Further, he states that the integrated servopump’s energy efficiency is far greater than that of conventional solutions, and so it is ideal for all direct linear motions when dynamic response, reproducibility and reliability are needed.

The CLDP servodrive can be easily integrated into new or existing machines. Only the electrical connection for the servomotor is needed.

Customers from diverse industries, such as oil and gas, energy, mining and metal processing, mechanical engineering, shipbuilding, rail and commercial vehicles, can benefit from this technology.