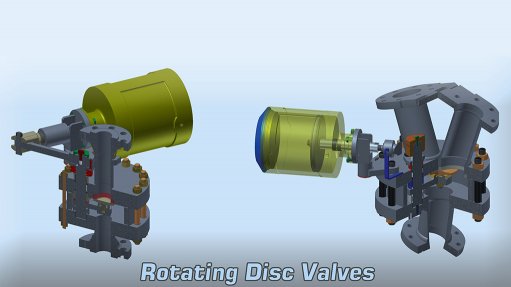

SELF-LAPPING ROTATION The valves’ metal-to-metal seating makes them abrasion resistant

Valve and desuperheater designer and manufacturer Mitech has supplied its range of rotating disc valves – suitable for abrasive media – to various mining operations in South Africa, including platinum mining major Anglo American Platinum’s Waterfall Smelter mine, in Rustenburg, and gold mining major AngloGold Ashanti’s Western Deep Levels mines, in Johannesburg.

“These valves feature a unique rotating, or shearing, disc that provides a self-lapping rotation and enhanced seat-cleaning action that cuts through solids, giving a long-lasting tight shut-off,” explains Mitech senior engineer Peter Connan.

Mitech’s bulk materials version of the rotating disc valve, which is designed for pneumatic conveying of powdered mediums, has been successfully applied at cement and furnace ash operations, while the diverter valve, which has a single inlet and two outlets, allows for fluid to be directed down the two outlet pipes at will.

“Both valve types have been successfully applied at backfill mining operations,” says Connan.

The rotating disc valves’ metal-to-metal seating makes them abrasion resistant over a wide temperature range. In addition, their high pressure capability allows for the force generated during use to be distributed over a larger area, resulting in reduced trim wear.

The rotating discs continually lap themselves to the valve bonnets during operation, while the downstream seat is energised by the process fluid, which ensures that there is a good seal, even under arduous conditions, says Connan.

Further, an abrasion-resistant full port eliminates obstruction to flow, with minimal pressure drop, while the self-draining body reduces the chance of jamming that could be caused by material entrapment, stagnation and degradation. A spring-loaded connection between the disc and drive enables the disc to compensate for thermal expansion or contraction. The connection also adjusts for wear, ensures tight shut-off and resists back pressure.

Additional features of the rotating disc valves include body-purge connections – which have the ability to flush valve cavity and internals while in operation – flat seating surfaces, repairable seats and a simple but versatile design.

The valves accommodate various media, including steam, coke, fly ash, ash slurry, flammable liquids and gases, sand and boiler water.

“The valves are good value for money for mines, as they have minimal parts and a long service life. This also reduces the need for regular maintenance. Prices for the valves vary according to the different sizes and clients’ product specifications,” he concludes.