During the last 12 years, Level 2 BBBEE agricultural and industrial mechanisation equipment supplier AIM has focused on designing state-of –the-art equipment to introduce the latest technology into the mining sector. This is achieved by teaming up with original equipment manufacturers (OEMs) such as Perkins, Caterpillar and ZF, and making use of industry leading engineering tools in our in-house design office.

Historically, diesel trackless mining machinery were very basic equipment, and in many cases it was agricultural tractors that were converted into machines that conformed to the mining requirements of that time. On some aspects, the industry had to settle for what was available based on the technology level of that time.

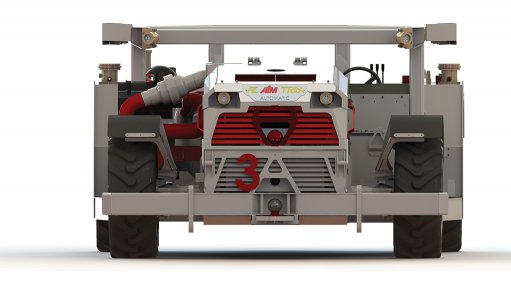

AIM has been at the forefront of the continued development of mining machinery which resulted in the FL-AIM-TRAX tractor series. These machines are setting the standard and introduces new technology to the South African mining sector.

One of our most notable development areas has been on machine control. In particular, it focuses on reliability of the drivetrain components.

By measuring, monitoring and limiting, our machine controllers are able to increase the reliability of the entire drive-train, from the engine all the way to the axles.

To name a few, our controllers are programmable to monitor fluid levels, fluid and housing temperatures, engine RPM, transmission output, machine payload, machine inclination etc.

Taking the above into considiration, we are able to set machine limits such as engine RPM and vehicle speed; limit engine power to protect drivetrain components such as drive shafts and axles from over torque.

Power transmission to externally driven equipment such as stone-dusters is also monitored for load and controlled to avoid damage to the drive components.

Level 9 intervention – proximity detection systems (PDS) / collision avoidance systems (CAS) – is also becoming a norm on all mines. In order to have a machine conforming to level 9 intervention requirements, certain machine drivetrain control abilities are neccesary. This includes, engine power control, transmission control and brake system control. AIM’s machine control interfaces seamlessly with all known PDS/CAS manufacturers and facilitates the control of power transmission by means of engine, transmission and brake control.

Our systems use state-of-the-art components of the highest quality.

It is programmable to suit each application and each end-user’s needs.

Taking all of the above into consideration, we are able to restrict the machine from operating outside its design parameters. Because of this, autonomous vehicles can also benefit greatly by making use of our machine controller and brake system.