Shutdown planning – the importance of defining its objectives

When planning to shutdown, a conundrum faced by all asset owners is how to compress the duration of the shutdown, and maximise the planned uptime of the assets – all without sacrificing the shutdown’s objectives. If the objectives, scope and deliverables are not clearly defined at the outset, the result is often constant scope creep, arguments, frustration, missed deadlines and excessive costs. Does this sound all too familiar? And, do your shutdowns typically play out like this: Your operations are stopped at fixed intervals and your Maintenance team delays its normal work to fill up this time. The result is that important work does not get done, or the shutdown exceeds its agreed time slot substantially. The ruinous combination of poor communication and vague objectives will markedly increase the likelihood of shutdown failure.

Teamwork

An important aspect of good shutdown management is a competent team approach with different stakeholders scheduled to deliver their work on time and in the correct sequence, allowing the shutdown duration to be as compressed as possible. This will minimise the operational losses or functional loss of capability as the plant is not operating. Only a disciplined end-to-end process delivered by an integrated team who works well together can achieve this.

Goals and objectives for shutdown planning

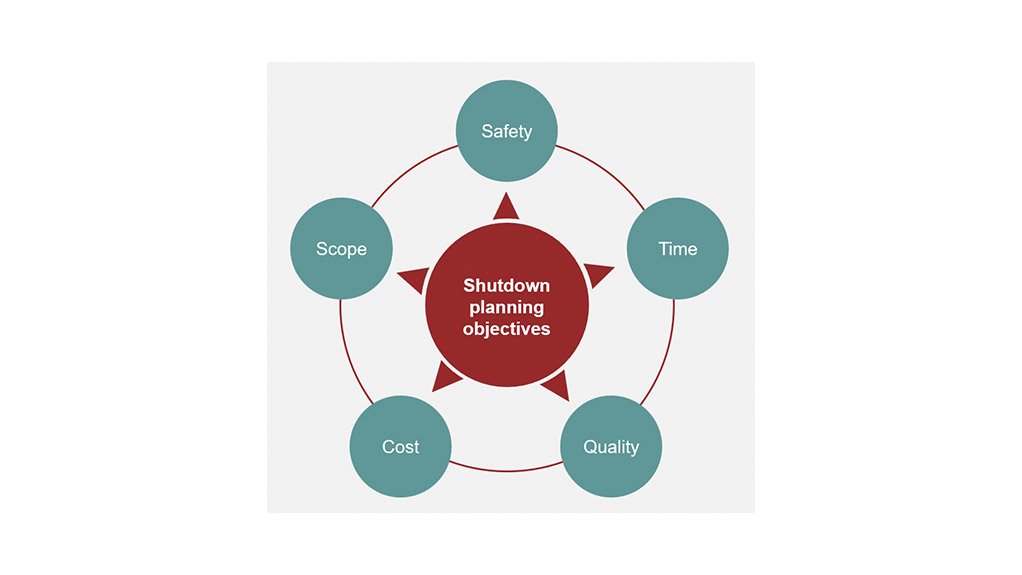

The goal of a shutdown is that the work completed during the shutdown will restore the condition of all plant and equipment to be safe and fit to perform its intended function once the plant is up and running post-shutdown. To achieve that goal, shutdown planning should always start with the definition of the shutdown’s objectives. Typical shutdown objectives would include safety and environment, time, quality, cost and scope.

The purpose of these objectives is to ensure decision alignment with all of the shutdown team members throughout the life cycle of the shutdown. Each defined objective should be treated with equal importance to ensure a successful close-out of the shutdown. However, objectives which are easily measured tend to garner more attention than those which are less “visible” such as quality.

- Safety and environmental – completing the shutdown with no incidents or accidents

- Time – completing the shutdown within the allowed time window

- Quality – completing the shutdown with no comebacks, downtime, or rework as a result of the shutdown activities

- Cost – completing the shutdown within the approved budget

- Scope – completing all of the planned scope, as well as essential emergent work within the shutdown

The shutdown objectives are then translated into metrics and key performance indicators. These are used to provide input into decision-making and analysis during the shutdown, and for continual improvement after the shutdown.

Many of these objectives are easily measurable and “visible” during the shutdown or are so interrelated that they become visible. For example, scope changes on a shutdown will invariably result in simultaneous time and cost over-runs and will be visible to all who are involved in the management and execution of the shutdown.

An invisible objective

Quality, however, is the “invisible” objective. It is all too easy to take shortcuts with quality to make up for time or cost overruns. These shortcuts are not immediately apparent nor visible to the management of the shutdown and only manifest themselves later as unplanned stoppages or failures. A small delay during the shutdown to detect and rectify quality problems is far less significant than an unplanned stoppage two weeks later. The question is: How do we make quality a visible part of the decision-making process for a shutdown?

Quality cannot be inspected in

It is a truism to say that quality cannot be inspected in. However, this is frequently forgotten and the focus for achieving the quality objective is often on inspection and test plans. These can only ever pick up problems after the fact. Planning for quality is an important part of overall planning for the shutdown. Questions that shutdown managers should ask are:

- Have we made sure that the people working on the shutdown are suitably qualified for the tasks that they have to execute?

- Have we defined quality criteria for the execution of critical activities? [This would include the execution tasks and safe work procedures, tolerances and specifications, and testing and commissioning checks.]

- Are our tools and equipment in good working order and have they been calibrated or tested as is appropriate?

- Are all the spare parts and consumables that we are using compliant with design specifications and standards?

- Are the contractors that we are appointing competent in their field? [Verification of this would include site visits to audit the competence and capabilities.]

- Is the working environment and access designed to be as comfortable and ergonomic as far as possible?

- And lastly, is there a culture of quality at the site? [This has to come from the top where management does not tolerate poor quality.]

Unless quality is built into the planning of the shutdown, a quality result is unlikely.

Who should be responsible for quality control during a shutdown?

Standard quality good practices dictate that the responsibility for quality control and inspections should be independent of the execution department. We know that this is not always practical on a shutdown: especially for mini-shutdowns or turnarounds.

However, there is much to be said for appointing independent quality inspectors that report directly to the shutdown manager. Execution supervisory staff are not wilfully negligent, but it is very easy to become over-extended during a shutdown and the one activity which is compromised is again the invisible one: quality. This results in check sheets being ticked off in the office without physical verification. The working relationship is also such that an element of trust exists between supervisor and tradesperson, and this may make the supervisor irrationally defensive and protective about their team’s outputs. So, wherever possible, an independent inspection team should be used.

Quality control tools for shutdowns

There are many quality control tools used in a maintenance environment. Some of these are more appropriate for routine maintenance and are not very useful during a shutdown.

Planned task observations (PTOs) are time-consuming but can have huge improvement benefits if used properly. Because of their nature, they are more appropriate for routine maintenance, where the results can be used and analysed for coaching and improvement opportunities. During a shutdown, there is just not enough time for PTOs.

Over-inspections are a concept which is sometimes used for a sample-based inspection of the results of a maintenance activity after the fact. They also have limited application within a shutdown environment. Over-inspections are often unstructured and undocumented. Simply put – they are not focused on the critical shutdown activities.

Selecting an effective tool

Due to the criticality and time constraints of a shutdown, there is only one formal tool type which can be used effectively for quality control. This tool is called an Inspection and Test Plan (ITP). It is also known as a Quality Control Plan (QCP).

The process for developing an effective ITP or QCP starts with the identification of the critical activities on the shutdown. What are those tasks, if executed poorly, will result in premature failures? The individual tasks within each of these activities and critical control points within the execution of that activity are identified.

For each of these critical control points, a hold point or witness point is assigned. A hold point means that the work must stop until an inspector has signed off that task’s deliverables. A witness point means that the execution staff must call the quality inspector, but they may continue with the work even if an inspector does not give sign-off.

For lower criticality tasks, a small sample may be inspected. High criticality tasks may use a 100% inspection regime.

A risk-based inspection and test plan allow for the most effective use of quality inspectors with the least disruption to the work execution.

It is an accepted fact that one cannot inspect the quality of the work without predefined quality acceptance criteria. These criteria should be unambiguous and easily measurable. Similarly, quality inspectors need to be suitably qualified, experienced and certified where required.

Commissioning: The final frontier

The commissioning of the equipment in the lead-up to the commencement of production is the final check on the quality of the work that was done. Defects found during the commissioning phase are already identified too late and should have been picked up earlier. However, it is better to pick these up during commissioning, than to have an unplanned shutdown two weeks after the plant is put back into operation.

Commissioning should be comprehensively planned to test the equipment’s performance. This starts at a component level where simple checks such as motor direction are done. This is then built up to verify quality through functional units and sub-assemblies until an entire process can be verified.

It is all too easy to skip some of the commissioning steps to make up time and to jump directly to the verification of the overall process, without verifying the performance of the individual components and sub-systems. As with other quality checks, the quality criteria should be defined and documented before the start of the shutdown.

To manage this process, a risk-based commissioning plan should be agreed upon at the start of the shutdown. Deviations to this plan should be very carefully monitored for risks to the overall quality.

Making quality visible in shutdowns

- Making quality visible to the decision-makers during a shutdown is not easy. Here are some recommendations:

- Measure and track the preparation for the shutdown to the quality of the inputs: ie the people, the tools, the contractors, and the other resources that are to be used.

- Develop quality control plans and commissioning plans and have them approved by a competent authority.

- Measure and track leading quality indicators like inspection success rate, and report and analyse these at all shutdown control meetings.

Include an evaluation of the effect on quality in all critical shutdown management decisions. This should, if at all possible, be quantitative and based on statistical projections and make financial projections for each possible option. While this is not easy, it forces the discipline of quantifying the effect of poor quality – even if the statistical confidence level is low.

Conclusions

The quality objective is indeed often “invisible” and is not part of decision-making during a shutdown. The consequences of this can be significant, especially if it involves a breakdown after the plant has been put back into service. It is, for this reason, we need to pay special attention to our quality management processes. In particular:

- Quality needs to be planned into the shutdown by making sure that all the inputs and resources used in the shutdown are competent and/or fit for purpose.

- If at all possible, the quality inspection team should be independent of the execution team and report directly to the shutdown manager.

- Inspection and test plans need to be defined before the start of a shutdown. These should be risk-based, focusing on the critical equipment and tasks and allowing for the effective use of inspection staff.

- Commissioning should be executed thoroughly, as this is the final quality check on the work.

Every shutdown team should make quality a part of the decision-making at all stages of the shutdown project. Often, in the rush to get a plant back online, it is all too easy to let the other objectives dominate, potentially resulting in significant consequences at a later stage.

This article first appeared on https://bit.ly/3znxIWZ

Pragma