QUALITY CONTROL Using the correct charge-up instructions and procedures lead to successful blasting results 80% of the time

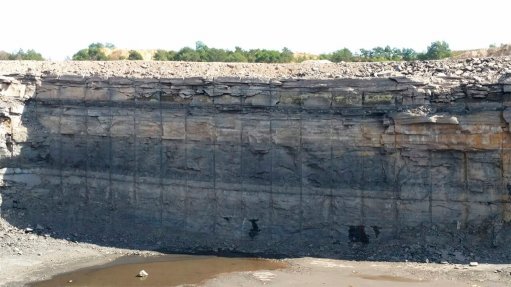

Quality control is the most important factor in conducting blasting at an opencast mine, says environmental, opencast and civil drilling and blasting company DynaD director Chris Bester.

He states that using the correct charge-up instructions and procedures, which include the quantity of explosives charged per hole and the correct tie-up design, lead to successful blasting results 80% of the time.

It is also important for a blasting company to be familiar with new products and blasting techniques, he adds.

“For this reason, DynaD meets with its suppliers monthly and works closely with them to be aware of new products and methods on the market. We also attend seminars on blasting and drilling.”

Bester further tells Mining Weekly that DynaD’s supplier – industrial explosives and blasting accessories manufacturer Sasol Nitro – has a technical and engineering team dealing with vibration and sound impact monitoring, as well as with blast pattern designs to address geological challenges.

DynaD, in turn, supplies its clients with drill operators, user manuals and contractor packs to enable them to understand which drill rigs and machines are suitable for their specific job.

“Therefore, clients do not have to deal with the drill and blast logistics and responsibilities, which enables them to focus on other areas of their mine operations,” says Bester.

Training

Bester tells Mining Weekly that DynaD’s staff undergo a full medical and fitness examination once a year.

If an employee is found to be unfit for duty, his or her report is referred to an external medical doctor for assessment and diagnosis.

“When the employee is diagnosed, he or she will join a remedial programme or get medicine for treatment until he or she is fit for duty. If an employee is diagnosed with a chronic disease, the person will be given a job description that will enable him or her to perform accordingly. Alternatively, an employee can also be put on light duty according to a doctor’s recommendations,” explains Bester.

He adds that staff also undergo training every six months or once a year which is Mining Qualifications Authority-certified. “This is to ensure that employees fully understand the risks associated with their job, are aware of the correct drilling methods and are familiar with the most productive way of operating the machinery.”

Regular training also ensures that employees fully understand their tasks at an opencast mine for overburden, midburden or coal drilling, Bester adds.

He says DynaD staff also have to complete a full induction programme that explains the risks, dangers and rules of a client’s specific mine site.

Further, the person in charge of the blasting site also does daily checks, such as planned task observations, where DynaD operators are taken through all the necessary proce- dures regarding the specific task they have to perform.

“The documents are signed off by all the parties concerned, and the process takes only about 20 minutes. These documents are kept for three years,” he says, adding that the person in charge also keeps a daily logbook that contains information, such as daily high-wall conditions and risk assess- ments, as well as the personal protective equipment and clothing needed by on-site personnel.