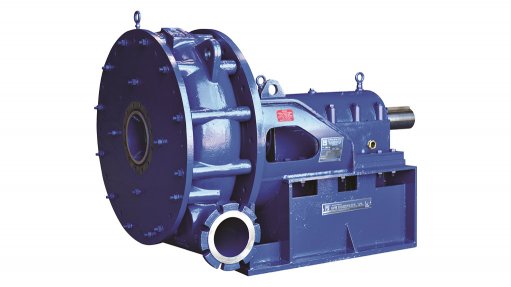

LSA PUMP The company offers pumps for various applications within the plant

Local pumps manufacturer KSB Pumps and Valves has won a multimillion-rand tender to supply locally manufactured specialised slurry pumps to minerals and metals processing specialist Outotec for the large-scale greenfield Mutoshi copper and cobalt mining project, in the Democratic Republic of Congo.

Owned by multinational copper and cobalt mining and metals company

Shalina Resources, the project, which is near Kolwezi, will require 80 specialised slurry pumps for its first phase of operation, with a requirement for additional pumps for its second and third phases.

The supply of pumps forms part of a global cooperation agreement between KSB Pumps and Valves and Outotec for the supply of slurry pumps internationally to complement the company’s high-quality processing equipment and services.

KSB Pumps and Valves slurry pumps manager Rob Bond says owing to the severe nature of the process, the pumps will be supplied with wear parts manufactured from a variety of exotic materials, including high-chrome irons, that are able to withstand the highly abrasive and acidic processing environment of the mine. All pumps, including specialised castings and seals, will be manufactured in South Africa.

The pumps for the initial phase will be delivered this year and include the company’s LSA pumps, the metal and rubber-lined LCC pumps as well as the vertically mounted close coupled LCV pumps for various applications ranging from pumping for grinding mills and thickeners to filters and tailings within the plant.

More Pumps

Strong demand for high efficiency vertical pumps has prompted KSB Pumps and Valves to manufacture a comprehensive range of advanced vertical turbine pumps for a range of applications including the mining industry.

The new B-Pumps are multistage vertical turbine pumps with a submerged hydraulic system comprising strong and efficient discharge casing assemblies, column pipes and pump bowls in the assembly. Depending on the size and application required the new range is available in 17 sizes with three different impeller types.

According to KSB Pumps and Valves sub-Saharan Africa regional sales manager David Jones, the pumpsets cover heads of up to 200 m and flow rates of up to 720 ℓ/sec with anything from one to 25 stages.

Stage casing diameters range from 15.24 cm to 61 cm with various designs, allowing above-floor or underfloor discharge. B-Pumps can be driven by vertically mounted electric motors or through a right-angle gear with a horizontal diesel engine or electric motor. The maximum permissible speed is 3 500 rpm.

A range of materials can be specified including standard grey cast iron and steel derivatives or special material including stainless steel, duplex and super duplex stainless steel or customised materials. Internally, the pumps have intermediate pump shaft bearings which are lubricated by the fluid handled, or may be fitted with an external lubrication supply.

Externally, the casing is designed for a pressure of 16 bar; the discharge flange dimensions are compliant with DIN, BS and ASME standards. On request, pressure ratings above 16 bar can also be supplied. The maximum temperature of the fluid handled should not exceed 105 ºC.