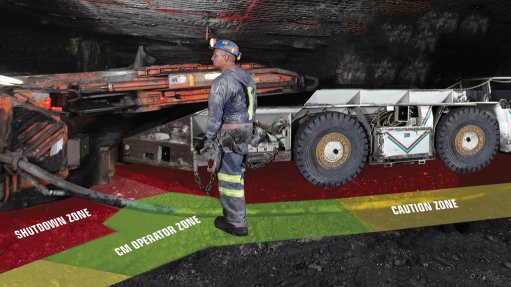

INTELLIZONE PDS

After a successful trial in 2015, the proxmity detection system was launched in South Africa in April last year

Photo by: Monitech

Although proximity detection systems (PDS) are not a new concept, their roll-out in the South African mining industry is on the increase, with uptake escalating in light of legislation introduced by the Department of Mineral Resources (DMR) under the Mine Health and Safety Act (MHSA).

A clause in the MHSA states that all trackless mobile machinery (TMM) should be fitted with a PDS by June 2019.

In line with this legislation, specialist safety and monitoring solutions provider Monitech is in the final stages of completing the supply, installation, commissioning, and training contract, in terms of its Matrix Design Group IntelliZone PDS, at integrated coal miner Sasol Mining’s underground operations, in Mpumalanga and the Free State, in South Africa.

Sasol Mining required assistance in complying with the regulations as set out in Chapter 8 of the MHSA of 1996, amended in February 2015, in terms of a PDS to ensure the safety of its personnel while interacting with underground mining TMM.

After a successful trial in 2015, the PDS was launched in South Africa in April last year, and the latest version of the IntelliZone system at Sasol Mining is the first installation of the technology in the country.

“Sasol Mining called for a reliable, effective, accurate, low-cost-of-ownership solution with seamless 24/7 qualified service and support. Integration had to be timeously completed, with minimal impact on mining operations,” Monitech CEO Jarrod Hassett explains to Mining Weekly.

He adds that the PDS also assists in mitigating extensive capital spend by the mining sector through system robustness and reliability affording the least impact on production.

“Monitech is proud to have the exclusive rights to distribute the Matrix IntelliZone PDS on the African continent,” Hassett explains, noting that Monitech and US-based mining technology expert Matrix Design Group has formed a strategic partnership to advance mining safety systems in their entirety.

Initially developed in 2009, the IntelliZone is the leading PDS used on TMM in the US coal mining sector, with the latest version launched in 2012, he notes.

“The IntelliZone PDS exceeds the industry’s expectations, and, together with the IntelliZone Precise Programmable Zone Technology, reduces nuisance warnings and shutdowns, affording increased production time.”

Hassett emphasises that the IntelliZone PDS is easily configurable and customisable to meet Sasol Mining’s requirements and forms part of the “zero harm” philosophy in mining, as adequate awareness of the PDS ensures that the TMM avoids pedestrians when they are in close proximity to the equipment.

From its offices in Benoni, Monitech – established in 1995 – supplies “around-the-clock” technical equipment and parts support for all installed systems, including the IntelliZone PDS, and aims to offer its clients the highest level of support.

“Monitech prides itself on recruiting only the most highly trained technical experts, all of whom are vastly experienced in the underground mining environment,” says Hassett.

Their training at Monitech covers Matrix PDS and associated equipment, as well as assembly, testing and fault finding. Employees are also sent to the US to receive training on the IntelliZone PDS and to tour the Matrix Design Group manufacturing plant, in Evansville, Indiana.

Monitech believes in developing and supplying high-end technical solutions and, therefore, aims to deploy the best technologies available in the South African mining industry with global expansion ongoing.

“Monitech showcased its equipment at the MINExpo trade show in September last year, in the US, which generated significant levels of international interest,” Hassett enthuses, noting that the company is targeting the international mechanised mining markets.

He further explains that Monitech identifies customer-specific requirements through engagement, as well as extensively researching available technologies to develop bespoke solutions.

The company, Hassett concludes, is developing various solutions, inclusive of the mining sector, which Monitech believes “will add value to our existing portfolio and meet the current end-user requirements regarding safety.