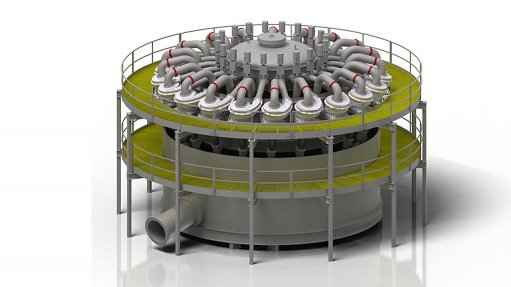

MHC SERIES HYDROCYCLONE The MHC Series has been designed specifically for grinding circuit classification duties

In response to mining industry needs, diversified engineering group Metso has introduced a “new generation” of fine classification technologies, the MHC Series hydrocyclone and ultrafine screen.

The company explains that these new offerings make it easier for customers to adopt next-generation fine classification technologies to improve efficiency and profitability. “These products position us as a unique supplier of fine classification technologies capable of optimising customer applications,” Metso asserts.

The MHC Series has been designed specifically for grinding circuit classification duties and was developed in collaboration with Metso’s “world-class” simulation and modelling scientists. The company further states that the design focuses on ensuring optimal process performance, superior wear component design and improved ease of maintenance.

“These new hydrocyclones are ideal for classification duties ranging from primary grinding to fine regrinding applications across the full range of mineral types.” The company comments that the new product improves Metso’s existing equipment offering, which covers the supply of entire grinding circuit systems to its customers.

Moreover, Metso notes that horizontal and vertical grinding mills, instrumentation and controls, mill discharge pumps and slurry hose products are also part if its offering.

In the area of wet fine screening classification, the company’s new ultrafine screen provides “one of the most accurate and cost-effective” separation technologies by reducing miners’ energy and water consumption.

Metso highlights that the new screen directly classifies particles by size using the physical dimensions of the screening media aperture. The company also notes that the improved separation efficiency and resulting reductions in materials handling and comminution energy lead to substantial savings in overall operating costs.

Additionally, it notes that screening performance is influenced less by plant operational variability and can positively impact on downstream recovery processes. Moreover, Metso contends that its solution broadens the application of fine wet screening technologies in the industry.

The company attributes this to the screen’s “innovative design”, adding that, with several patents pending, its ultrafine screening technology is more accessible to a greater variety of customers on a wider scale. “The reduction in the overall capital expenditure . . . and . . . operating costs allows customers to quickly pay back the investment, leading to higher profitability,” Metso asserts.

Further, the company remarks that, relative to other fine screen technologies, its ultrafine screen doubles the screening area of a single machine. It says that this is achieved through the technology’s modular design consisting of up to ten individual screen decks nested together into a single vibrating assembly, along with a feed distribution system to ensure accurate and even feed distribution across the width of each individual screen deck.

“This reduces the space and infrastructure required for integration into the plant,” Metso concludes.