HXM BLAST Viewing the volume of influence solids and polygons will be among the features of MineSight's new blast technology

The June 2014 acquisition of US-headquartered mining software developer MineSight by design, measurement and visualisation technology provider Hexagon AB to form its new division, Hexagon Mining (HxM), has created many possibilities, highlighted by MineSight’s new data repository and analytics system, HxM Athena, HxM chief innovation officer for planning Glenn Wylde tells Mining Weekly.

He states that HxM Athena – to be launched at MineQuest – MineSight’s yearly customer seminar in Tucson, Arizona, from April 13 to 17, 2015 – has a bigger and better scope than its predecessor, the 2012 MineSight Performance Manager.

Wylde adds that not only is the system a repository for all data that imports, validates, analyses and stores information from multiple sources in single central data hub but it also includes viewer and mobile applications, enabling site-wide query and analyses.

HxM Athena provides a clean, engineered pathway to share data between HxM-acquired companies, which are openpit mining technology providers Leica Geosystems and Jigsaw, underground solutions provider Devex, and open mine traffic safety solutions provider SAFEMine, MineSight senior product manager for geology and operations Mark Gabbitus states.

“Mining is becoming a more precise practice, and accurate mine planning and scheduling are at the forefront of this change. Hexagon has been active, primarily in the operations domain, but the integration of MineSight’s planning, scheduling and daily production capabilities enable Hexagon to close the loop and control data flow across all mining operations,” he says.

The MineSight acquisition provides a platform that allows for a clear flow of information and knowledge throughout the mining process – from the mine planning system (MineSight’s domain) and operations (Leica Geosystems’ domain) to the final destination of the mill.

This flow goes both ways, so that those at the mill can follow what is intended and those in planning can improve their practices, he adds.

“We arrived at a point where we had a great product for mine planning or body modelling, but the world has changed, so that things now have to be interconnected,” MineSight founder and chief technology officer Fred Banfield states.

He says that, in conjunction with other companies within HxM, MineSight no longer has to be compromised because of limited size or lack of appropriate technologies, which previously made it difficult for MineSight to develop software that could synthesise the operations of all the mine components.

All the companies acquired by HxM will maintain independence at product level; therefore, MineSight will continue to service and enhance MineSight products while working on synergistic products with its Hexagon mining partners.

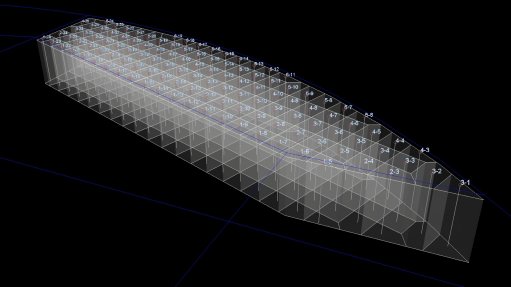

HxM will release another new product – the HxM Blast – at MineQuest.

The software system will be able to store and manage drill and blast patterns in a database, which will allow for a comparison between the planned and actual results of blasting.

The improved workflow and functionality of HxM Blast – compared with MineSight’s previous Blast Pattern Editor – mean that the blast design and management software make work easier for the drill and the blast engineer at this crucial stage of the mining process.