Name of the Project

Mt Peake vanadium/titanium/iron project.

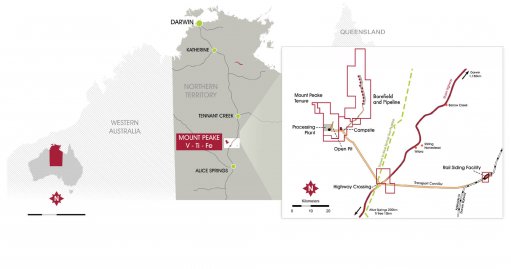

Location

Northern Territory, Australia.

Project Owner/s

TNG.

Project Description

As part of the ongoing front-end engineering design (FEED) process for its Mt Peake project, TNG has optimised its planned execution and delivery strategy for the project, delivering savings and reductions in upfront capital costs while maintaining robust economics.

Discussions have confirmed that simplifying the project towards a one-stage build while minimising capacity and capital expenditure is best suited to the targeted debt/equity structure for the project.

The Mt Peake mine site will involve mining the titanomagnetite ore and recovering the magnetite in a concentrate through a beneficiation process.

The company and its advisers have selected a development strategy based on an initial production rate of two-million tonnes a year of ore throughput at the beneficiation plant, corresponding to 100 000 t/y of titanium oxide pigment through the proposed TIVAN processing plant. At a later date, after the financial completion of construction and operation of the two-million-tonne-a-year plant, TNG may consider the option to expand production capacity.

Previous feasibility studies were conducted using three-million tonnes a year of run-of-mine (RoM) production capacity during an initial production stage and increasing capacity to six-million tonnes a year of RoM by expanding the plant after four years of production.

Under the new mining schedule, the life-of-mine (LoM) has been extended to 37 years, from the previously planned 20-year LoM.

Potential Job Creation

Not stated.

Net Present Value/Internal Rate of Return

The updated pretax net present value, at an 8% discount rate, is estimated at A$2.8-billion, with an internal rate of return of 33% and a payback of 2.8 years.

Capital Expenditure

Preproduction capital expenditure is estimated at A$824-million.

Planned Start/End Date

Not stated.

Latest Developments

TNG has reported that it will progress the development of the Mt Peake project with a fully integrated mining and processing operation within its existing mining leases.

The selection of the Mt Peake mine site for its downstream TIVAN processing facility follows a detailed assessment of alternative sites.

The strategic assessment review included quantification of the potential operational, regulatory and commercial risks of having a consolidated and integrated mine site operation, compared with a standalone TIVAN processing facility in Darwin.

An integrated mine-beneficiation-processing facility was originally considered at the Mt Peake mine site in the initial project scoping study; however, at that time, gas and water availability was considered inadequate to meet the project’s requirements.

As a result, a number of other sites were assessed for the location of the TIVAN processing facility, including Alice Springs, Tennant Creek, Pine Creek and Darwin. The company also considered an offshore site in Kuantan, Malaysia, and a site near Whyalla, in South Australia.

“This is the most important change to the configuration of the Mt Peake project since the completion of the feasibility study and, importantly, it [provides] . . . certainty . . . [for] all . . . our key stakeholders, our project financiers, our shareholders and everyone else who has followed our journey to date,” TNG MD and CEO Paul Burton has said.

TNG is working with its key engineering and contracting partners to develop an updated project delivery schedule and progress with permitting as quickly as possible.

Key Contracts, Suppliers and Consultants

Snowden Mining Industry Consultants (revised mining strategy); Como Engineering (beneficiation plant – recoveries, operating expenditure and capital expenditure); McMahon Services (infrastructure – operating and capital expenditures); SMS (process plant flowsheets); and METS Engineering (process plant construction and operating expenditure).

Contact Details for Project Information

TNG, tel +61 8 9327 0900 or email corporate@tngltd.com.au.