ATOMISED MISTING TECH The kinetic energy pushes the atomised droplets to the heat source, therefore, the fire will lose its energy rapidly

While most companies try to remove at least one of the factors necessary for a fire to exist when putting out a fire, environmental solutions company I-CAT’s Fire Solutions removes at least two components.

The four factors required for a fire are fuel – any substance that can combust; heat – heat energy sufficient to release vapor from the fuel and cause ignition; an oxidising agent – air containing oxygen; and an uninhibited chemical chain reaction – sufficient exothermic reaction energy to produce ignition.

“Our fire suppression systems remove the heat element by rapidly cooling down the heat source and we also displace the oxygen away from the source of fire,” says I-CAT product specialist Carla Janse van Rensburg.

Van Rensburg adds that I-CAT offers a range of technologies that are dynamic, innovative and effective, exceeding client expectations. The majority of I-CAT’s fire suppression products all use specialised T-Rotor misting technology.

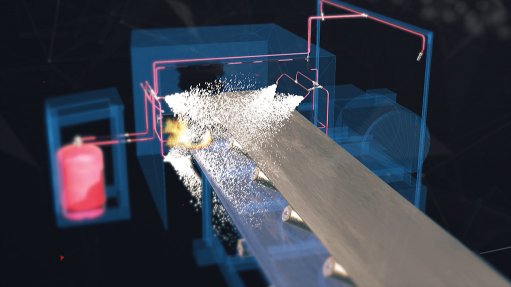

The technology effectively atomises water and charges it with enough kinetic energy to suppress fires.

The droplet size of the mist measures from 55 μm – which is about half the size of a human hair. The kinetic energy pushes the atomised droplets to the heat source, therefore, the fire will lose its energy rapidly. The heat would transfer from the fire into the atomised droplets, subsequently dispersing that energy away, she explains.

The misting technology uses low pressure systems that range between 14 bar and 17 bar, compared with other high-pressure fire suppression systems that can reach up to 300 bar. This makes it safer for a person operating the system, adds Van Rensburg.

She further emphasises the high value of mining vehicles, noting that it is vital to safeguard this equipment, as well as the individuals who operate it. The I-CAT Vehicle Suppression Systems use I-Protect linear heat-detection tubing that detects temperatures between 150 ºC and 180 ºC. The system is equipped with specialised discharge nozzles that safely and efficiently suppress fires and cool down engine compartments, the operator cabin, wheel arches and the brakes of vehicles such as buses, heavy-duty mechanical vehicles and armoured vehicles.

Van Rensburg warns that, regarding conveyor belt fires, the fire is not necessarily the most dangerous, rather, the toxic gases emitted from the conveyor belt itself when on fire, are.

The surface and underground conveyor belt suppression system is currently one of the most common applications for I-CAT’s Localised Suppression Systems.

Additionally, the I-Protect fire suppression system is an ideal solution for restricted or small enclosures containing valuable electrical equipment housed in substations and electrical cabinets. The suppression system is a low-pressure pneumatic automatic system that is a direct, quick response application, she explains.

“There are multiple factors to consider when choosing a fire suppression system. Companies need to be aware of the effect the suppression agents have on the equipment after it has been released.”