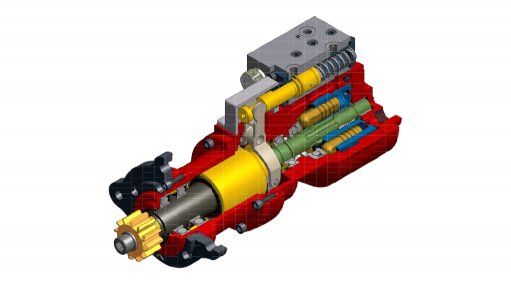

HYDRAULIC STARTER MOTOR Powerworks believes its starter motor is the only one of its kind

Johannesburg-based hydraulic starter motors manufacturer Powerworks’ pre-engaged hydraulic starter motor, which was certified as compliant with European directive Atmosphere Explosives (Atex) requirements in 2011, is being well received globally.

Powerworks technical director Nick Ruberg tells Mining Weekly that the company’s success throughout its three-decade existence is attributable to its dedication to rendering services in record-breaking time and providing first-class service to support its products.

He says that, in recent years, the company has received numerous orders for the hydraulic starter from companies in the mining, power, construction and other industries across the globe.

Ruberg says the starter motor is the only one of its kind globally and that the Atex recognition signifies its importance.

“We differ from other manufacturers because we have a wealth of experience in installing and repairing starting systems. What is most special about our hydraulic starter motor is that it requires no electricity and is nonsparking, which makes its ideal for flameproof applications,” he adds.

Ruberg says the company’s starting system offers more power and torque per kilogram than electric starters. It is also lighter than electric and battery-powered starters.

The hydraulic starter motor is sealed and resistant to contaminants, such as coal dust and corrosive salt spray, or any other harsh environmental conditions. Further, all the starter’s moving parts are submerged in oil.

“The hydraulic starter comes with the option of fitting beryllium copper pinions for nonsparking applications. It can be recharged manually through an optional hand pump. The starting system is also unaffected by temperature extremes and can function below freezing point,” Ruberg elaborates.

Energy is stored in the form of hydraulic oil under pressure inside the piston accumulator.

The recharging of the system can be done manually using a hand-operated pump, electrically through a hydraulic pump or through the host machine’s on-board hydraulics, if applicable.