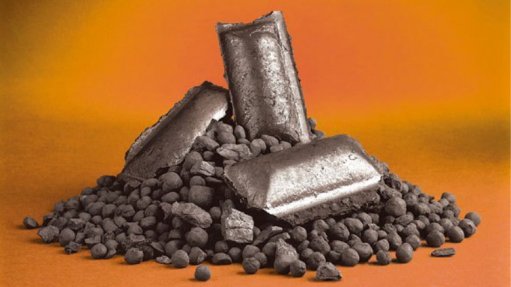

Direct reduced iron is a raw material for steelmaking made by reducing iron-ore.

Japanese steelmaker Kobe Steel is collaborating with the iron-ore major Vale and global trading and investment company Mitsui on providing low carbon dioxide (CO2) iron metallic and iron-making solutions.

Kobe says the direct reduction iron-making technology of its US subsidiary, Midrex Technologies, is expected to play an important role in promoting the low CO2 initiative.

The Midrex process uses natural gas, or gas derived from coal, to reduce iron-ore for use in steelmaking. Kobe says its CO2 emission level is lower than that of blast furnaces.

“Kobe Steel is contributing to reducing CO2 emissions through various products, such as high tensile strength steel sheets for automotive weight reduction. However, as the CO2 emissions arising from the steel manufacturing process are also an issue from the standpoint of climate change, there is a growing need worldwide to reduce CO2 emissions in the steel industry,” the company says in a statement.

Direct reduced iron is a raw material for steelmaking made by reducing iron-ore.