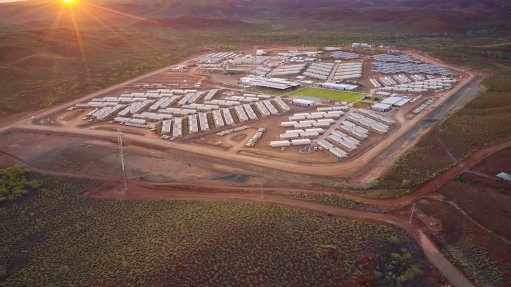

Photo by: Fortescue Metals Group

Name of the Project

Iron Bridge magnetite project – Stage 2.

Location

The project is located 145 km south of Port Hedland, in Pilbara, Western Australia.

Project Owner/s

An unincorporated joint venture (JV) between Fortescue Metals Group (FMG) subsidiary FMG Iron Bridge, or FMG IB, (69%), and Formosa Steel (31%).

FMG will manage and operate the project with full marketing rights.

Project Description

The project has a mineral resource of 5.45-billion tonnes, including an ore reserve of 716-million tonnes and a mine life of more than 20 years.

The Stage 2 development follows the $500-million investment in the successful Stage 1 construction of large-scale pilot and demonstration plants, which have validated key equipment and magnetite production processes for the full-scale Stage 2 ore-processing facility.

Stage 2 development includes:

- a 22-million-wet-metric-tonne-a-year ore processing facility (once at full operational capacity);

- an airstrip and expanded village;

- a 195 km canning basin water pipeline;

- a 135 km concentrate pipeline to FMG’s Herb Elliot port facility, in Port Hedland, and a return process water pipeline; and

- port handling facilities, including concentrate dewatering, covered storage and reclaiming/conveying, to existing port outload circuits.

The project aims to produce 22-million wet metric tonnes a year once full operational capacity is achieved. Iron Bridge will deliver a premium product with an iron content of 67%.

Potential Job Creation

Since the investment decision in April 2019, more than 12.8-million work hours have culminated in the design and construction of the mine, pipelines, village and infrastructure at Iron Bridge, supporting more than 3 000 jobs, with another 900 full-time jobs to be created when the project moves into operations. There are currently 3 470 people working across the ore-processing facility and pipelines scope of work.

Net Present Value/Internal Rate of Return

Not stated.

Capital Expenditure

$3.9-billion.

Planned Start/End Date

First ore is scheduled for the March quarter of 2023.

Latest Developments

FMG has produced its first magnetite product, after having its maiden production postponed, in addition to suffering significant cost blow-outs.

The project’s first run rate produced grades greater than 68% iron, with the concentrate now being transported through the 135 km specialist slurry pipeline, with dewatering and materials handling at Port Hedland creating a high-grade magnetite product, ready to be shipped and suitable for steelmaking.

Key Contracts, Suppliers and Consultants

NRW Holdings (bulk earthworks); and SIMPEC (wet processing plant construction).

Contact Details for Project Information

FMG, tel +61 8 6218 8888.

Formosa Steel, tel +886 2 2712 221.