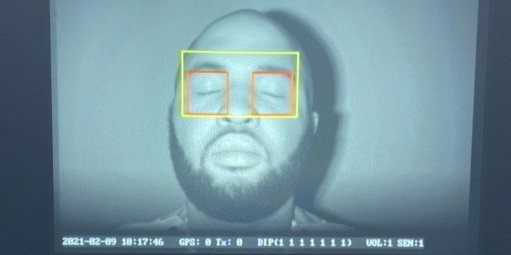

KEEPING AN EYE The fatigue detection system monitors a driver posture and eyes to predict fatigue trends

The South African mining industry continues to experience a disappointing safety record, with 74 people losing their lives on the countries mines last year. This is a 23% regression from the previous year, when 60 people perished.

According to the Minerals Council of South Africa, general types of accident and fall of ground are a key area for concern, with 22 general types of deaths (30%) reported in 2021, and 20 fatalities (27%) caused by fall of ground. However, transport-related accidents is also an area of concern, with 16 fatalities (22%) reported in this category.

Driver fatigue is implicated in a substantial percentage of accidents involving haul trucks and road transport crashes at mining sites. Because of this, fatigue monitoring is now recognised as a critical component of ensuring safer mining operations.

Favorsea Africa, which specialises in mining safety, productivity and automation systems, states that the most dangerous part about fatigue is microsleeps, which are bouts of sleep lasting less than 30 seconds. The danger is if a machine is travelling at 40 km/h (most surface mine speed limits) and the driver falls into a microsleep at this speed, the machine is able to travel about 40 m uncontrolled.

“Due to our passion for mine safety, we analysed the root cause of driver fatigue to ensure that we design our fatigue detection camera system with the end user at the centre of our design,” Favorsea MD Innocent Chimunhu.

The Favorsea fatigue detection system continuously monitors driver posture and eyes, thereby allowing tracking of driver behaviour to predict certain fatigue trends. The system can operate while the driver is wearing glasses.

The system can be programmed to slow down and stop the machine if a specific number of fatigue alarms is received within a certain time period. These can include detecting smoking, phones calls and persons not wearing seatbelts.

The software is enabled with tracking and positioning for analytics, enabling the back-office to determine where most fatigue events occurred. It also offers a dashboard with recording and replaying ability for up to 30 days, enabling replay and training purposes

Favorsea says the system interface is designed to connect directly to the machine or through most Level 9 Collision Avoidance Systems.

Hall 5 Stand F11