- BASF’s solutions help reduce plant energy consumption for sulfuric acid manufacturers

- New X3DTM technology to produce catalysts with optimal shape to achieve best performance and efficiency while reducing energy consumption

- Newly shaped O4-116 Quattro catalyst for the final converter bed significantly reduces emissions

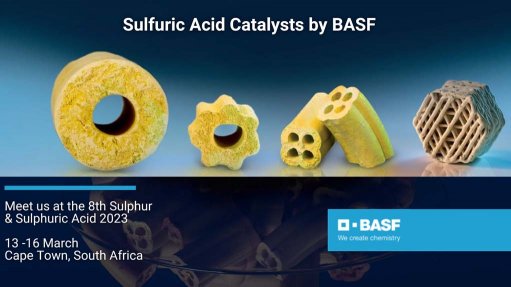

BASF will be highlighting its novel X3DTM technology, a new additive manufacturing technology for catalysts based on three-dimensional (3D) printing, and its newly shaped Quattro catalyst is revolutionising sulfuric acid production, during the Southern African Institute of Mining and Metallurgy conference, taking place from 13 to 16 March at Cape Town’s Vineyard Hotel in Cape Town, South Africa.

BASF introduced the novel X3DTM technology, a new additive manufacturing technology for catalysts based on 3D printing. Catalysts produced with this technology feature an open structure, resulting in a reduction of the pressure drop across the reactor and a high surface area, significantly improving the catalysts’ performance. BASF has capabilities to supply commercial quantities. The technology offers a greater freedom of catalyst design compared to conventional production technologies. Customers can benefit from an increased reactor output, higher product quality and lower energy consumption. The novel catalysts are mechanically robust and proven in commercial plant operation externally and for several years in BASF.

BASF also introduced the new sulphuric acid catalyst O4‑116 Quattro. The new, caesium-promoted catalyst is specifically designed for the final converter bed in sulfuric acid plants. Customers benefit from an ultra-low ignition temperature that brings emission reduction to the next level.

Contact our Sub-Saharan Africa team today: Enquiry here

Learn more: https://catalysts.basf.com/industries/chemical/sulfuric-acid