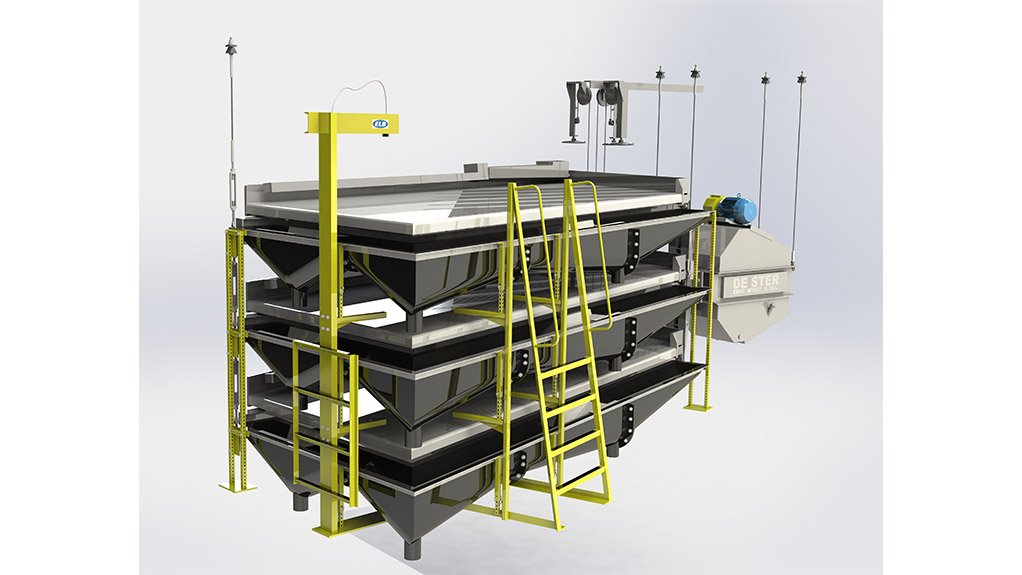

ELB Engineering Services (ELB) is pleased to announce that we have piloted and commissioned a fully automated control system to optimise the recoveries on spirals and shaking tables in the minerals beneficiation industry.

“ELB has successfully managed to use camera recognition and machine learning to identify the separation point between tailings and product. We have engineered this to a fully automated system, which uses a linear guide, controlled via the camera PLC to separate the materials,” says Josh Hodgkinson, ELB’s Intelligent Solutions - Implementation Engineer.

This will optimise recovery of the plant and eradicate product dilution or product to tailings, as the cutter is adjusted every three to five seconds.

ELB uses the latest in camera technology and incorporates an intelligent system which will allow optimised beneficiation across the chrome, iron ore, heavy sands and high density ores including gold, tin, copper, rare earth industries, to name a few.

ELB Engineering Services is an internationally recognised, know-how solutions provider to the mining, power, port, construction and industrial sectors. This is achieved through ELB generated innovation, supply of equipment and technology from our world class partners, in-house developed expertise and integration of the services and products from the ELB Group of companies.