Having spent 30 years researching and developing original products to reduce particulate matter (PM) from global industrial sources, air filtration solutions provider Aircure is launching three “revolutionary” products in July – the Cycloduct, the Cyclogrit and a shipping container baghouse, the Baghouse SC.

The products are designed to radically reduce PM emissions and dust control for a broad range of industries, including power generation, mining, paper, steel foundries, petrochemicals, sugar and cement.

“Aircure’s innovations have the data and research pedigree to be described as groundbreaking.

“Using computational fluid dynamics (CFD) modelling to perfect ongoing testing over the past several years, the Cycloduct and the Cyclogrit consistently outperform environmental and industry targets required for air pollution control in South Africa and globally,” says Aircure owner Darren Bibby.

Research and development is essential to ensure that companies comply with the necessary legal limits without undue issues, whereby the use of CFD modelling removes uncertainties and allows for integration prior to installation, he adds.

New Products

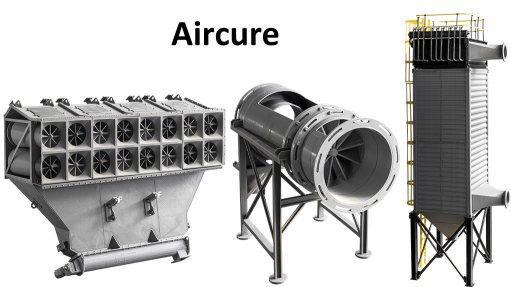

To meet the gap in many industries and sectors, Aircure offers its Cycloduct and Cyclogrit cyclonic separation systems for which numerous international patents have been granted.

The Cycloduct is a single unit typically installed in a circular ducting, while the Cyclogrit is a modular cyclonic separation system comprising various Cycloducts placed within a square or rectangular framework.

The horizontal cyclones harness the principle of centrifugal force that drives the removal of particles from an airstream.

Cyclonic separation is now able to increase the overall efficiency of new and existing filtration systems, and Aircure’s cyclones can be retrofitted to most existing filter types, thereby allowing for cost savings by extending the life of the downstream components.

Moreover, Aircure’s cyclones are designed “in-line” – they can, therefore, be adapted to all duct types and shapes.

“This system is so unique that the patent application extends to 75 countries around the world,” says Bibby.

The Cycloduct was developed for underground gold mines as pre-filters to Aircure’s silicosis reducing filter systems. The Cyclogrit collector was designed for energy and chemicals company Sasol for use in its coal-fired boilers as a pre-filter to the Electrostatic precipitator.

The cyclonic separation systems have been applied as a component for the ‘simple, leading practice’ for mine occupational health and safety, and installed in most South African gold mines.

Baghouse SC

The shipping container baghouse is completely modular and can be scaled to

large-volume units while offering quicker manufacturing and installation, easier transportation logistics and a decrease in production downtime. Aircure first began designing baghouses from shipping containers in 2015.

With the price of steel having increased by almost 65% in the past 18 months, Bibby notes that, by using A-grade shipping containers to construct the baghouses, customers can save up to 30% on manufacturing costs.

“Building unique equipment requires modelling, testing, proof of concepts in a wide variety of industries, case studies, patent approvals and product refinement. We are finally at the point where we can proudly reveal these incredible innovations as a South African company with world-class designs and engineering prowess.”

Amid more emphasis being placed on the reduction of greenhouse gases and carbon capture, Aircure has embarked on projects for air pollution control for Sasol, papermill company Sappi and steel manufacturer Scaw Metals.

Bibby says removing PM improves the efficiency and maintenance costs associated with gas phase filtration.

“Removing tons of emissions from the atmosphere and preventing toxins from landing in water sources and on the ground are achievable now, and we think we can do it correctly.

“We want to assist all major companies battling with environmental compliance issues with a specific focus on PM emissions from fossil fuel applications. We have game-changing solutions that are impactful and cost effective,” he concludes.