Photo by: Strandline Resources

Name of the Project

Coburn mineral sands project.

Location

Gascoyne region, Western Australia.

Project Owner/s

Mineral sands developer Strandline Resources.

Project Description

The project has Joint Ore Reserves Committee-compliant ore reserves of 523-million tonnes grading 1.11% total heavy minerals for about 5.8-million tonnes of contained heavy minerals.

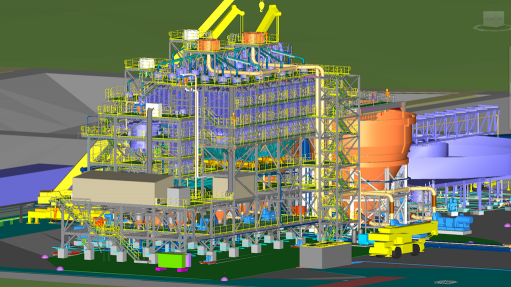

The June 2020 updated definitive feasibility (DFS) confirmed a conventional openpit dry mining operation, where free-dig unconsolidated sand is mined using heavy mobile equipment to transport material to dozer mining units. The units prepare the ore for processing and the ore is pumped in slurry form to the processing plant.

Bulk metallurgical testwork of representative samples using full-scale or scalable processing equipment has confirmed conventional processing capable of producing high-quality products, with exceptional pit-to-product recovery rates achieved within concentrate and the final product streams.

The DFS further confirms an efficient and modern process design capable of producing a high-grade saleable 95% heavy minerals concentrate product from the wet concentration plant (WCP), and final products through further processing by the mineral separation plant (MSP).

The project will produce four final products comprising a premium zircon product (66% zirconium dioxide), zircon concentrate product (payable zircon, titanium and monazite minerals), rutile product (93% titanium dioxide) and a chloride-grade ilmenite product (62% titanium dioxide).

The updated DFS is still based on a throughput of 23.4-million tonnes a year, with an average production of 34 000 t/y of zircon, 54 000 t/y of zircon concentrate, 110 000 t/y of chloride ilmenite and 24 000 t/y of rutile, which are expected to supply about 5% of the global zircon market.

There is potential to further increase project reserves and mine life by about 15 years – to 37.5 years – through the conversion of resources extending north and along strike of the current ore reserves.

Potential Job Creation

Peak workforce during construction is estimated to be more than 300 people, with an average operational workforce during production of about 150 direct skilled workers.

Net Present Value/Internal Rate of Return

The project has a pretax net present value, at an 8% discount rate, of A$705-million, up from A$544-million in the feasibility study. The pretax internal rate of return has increased from 32% to 37%.

The project has a payback of 2.1 years.

Capital Expenditure

Capital expenditure (capex) has increased from A$257-million in the DFS to A$260-million in the updated DFS.

Planned Start/End Date

The project will take 18 months to design and build to achieve first ore to the process plant.

Latest Developments

Strandline Resources has achieved commercial production of heavy mineral concentrate at its Coburn mineral sands project days after processing first ore at its wet concentrator.

Strandline is now focused on increasing production throughput towards design rates, improving plant availability and optimising product recoveries and specification. While ramp-up of the WCP continues, construction teams remain focused on finalising the downstream MSP and remaining support infrastructure.

Strandline expects to sell several shipments of heavy mineral concentrate produced from the WCP while construction of the MSP is being completed.

Key Contracts, Suppliers and Consultants

R Engineering Services, AMC Consultants (detailed mine plan), IHC Robbins, AECOM and TZMI’s Allied Mineral Laboratories (DFS); SRK Consulting (technical due diligence of engineering designs and planning associated with geology, hydrology, mining, processing, infrastructure, logistics, implementation strategies, cost estimates, and environmental, social and permitting?); Deloitte Access Economics (independent economic cost-benefit analysis); TZ Minerals International (product quality and marketing) and Macmahon (construction of road access and bulk earthworks); Piacentini & Son (in-pit dozer mining units) and Primero (engineering, procurement and construction, and commissioning and performance testing of the wet concentration plant, minerals separation plant and associated processing circuits); and Mine Site Construction Services (mining services contract).

Contact Details for Project Information

Strandline Resources, tel +61 8 9226 3130 or email enquiries@strandline.com.au.