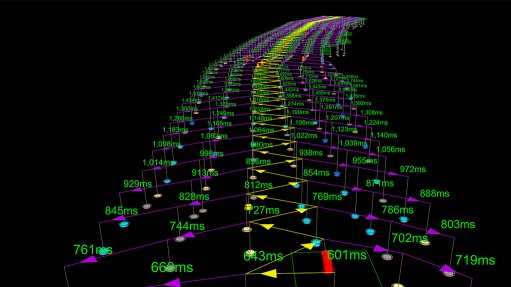

INTELLIGENT SOLUTION With BlastLogic, superior blast performance is achieved through fusing distinct data sets associated with mine planning, drill guidance, field surveys, load design parameters and post-blast evaluation to create a more intelligent blast design

Using mining software, hardware and services provider Maptek’s blast design and management system, BlastLogic, mines can pre-empt blast-related risk and productivity issues through the instantaneous sharing and visualisation of operational data.

“BlastLogic accelerates the process of creating and implementing accurate blast designs. Simultaneously, it provides measurements and reports on blast execution accuracy,” elaborates Maptek blast accuracy solutions manager Mark Roberts.

In August, Maptek presented this technology at the FragBlast 11: International Symposium of Rock Fragmentation by Blasting, in Sydney, Australia.

“The company was delighted to present the product to this global forum. FragBlast was a terrific way for us to connect with the people who use our products,” says Roberts.

Maptek developed BlastLogic in collaboration with industry, as customers rely on the technology to track, quickly understand and act on all factors that have an impact on drilling and blasting at critical stages.

Roberts explains this is achieved through real-time data integration, reporting and three-dimensional visualisation, which can be accessed by users throughout the blast design and execution process.

Linking blast designs directly with the geological model and field measurements enables mines to enhance precision in blasting and understand how this impacts on downstream processes, he notes.

“For example, if you are looking to optimise fragmentation to improve dig rates and crusher throughput, BlastLogic can quickly relate fragmentation results back to blast and geology parameters. The BlastLogic frag modelling tool helps engineers advance future designs and better inform operations of expected postblast ground conditions,” Roberts points out.

Maptek is aware that mines are increasingly approaching drilling and blasting with the entire mining process in mind.

“Customers are integrating drill and blast design with grade control and drillhole geophysical interpretation tools to validate the resource model and increase the recovery of minerals,” Roberts concludes.