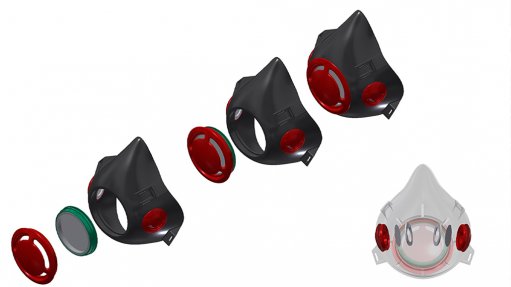

The Hudaco mask assembly.

Photo by: Hudaco Industries

JOHANNESBURG (miningweekly.com) – An awesome new proudly South African face mask, with a replaceable filtration system at its heart, is attracting international interest.

The innovative and timely Hudaco Air Mask is a lockdown-period product of the Johannesburg Stock Exchange-listed Hudaco Industries group. (Also watch attached Creamer Media video.)

It is all set to take the world by storm because of its unrivalled air-intake and air-exhaust effectiveness, ease of filter exchanging, skin friendliness, ongoing comfort and unmatchable price tag at a time when the prices of filtered Covid-19 and FFP2 facepiece masks have gone through the roof.

FFP2 masks are used mainly in the more difficult situations on mines, in foundries and in woodworking environments, where filtration is needed to keep out fine particles such as dust.

The development of Hudaco’s face mask came about when the lockdown idled the group’s production lines but not the minds of its executives.

Hudaco Industries CE Graham Dunford looked at the inactivity of the company’s injection-moulding capacity, and the fortunes companies were having to fork out on non-disposable Covid-19 masks, which utilise layers of FFP2 fabric in their filtration system. This was taking place while the system endorsed by a leading South African filtration manufacturer offered an alternative solution for FFP2 masks, for which certification for an FFP2 rating is pending.

Against that background, Dunford put to work a group that sources product from more than 800 international suppliers across the industrialised world and carries more than 230 000 line items in stock.

In many businesses, masks are discarded daily and “when you’ve got a couple of hundred or even thousands of employees, which they have on the mines, and when you’re changing masks that are costing you R55 each a day, it costs a lot of money”, said Dunford.

This prompted him to ask Hudaco executive consultant Mike Allnutt to look into ways of getting the company’s injection-moulding machines up and running while solving the worsening face mask problem.

The outcome is a comfortably fitting mask with a filtration system that provides a physical barrier against droplets of 5 microns in size, while changeable exhaust filters clean up exiting breath.

Consideration was foremost that the mask should be non-disposable and simple to clean for reuse, which would mitigate the environmental waste associated with disposable masks.

Food-grade specification DEHP-free material, or optional medically graded FDA-approved material, is moulded, and all component polycarbonate materials, such as the filter cartridge, nose shield and non-return valves, including rubber holding straps, have the stamp of approval of the FDA.

Importantly, the change-out of the mask’s filtration system is uncomplicated and the filter can be disinfected without any damage or misalignment. Detailed attention has been given to the means of disposing the user's exhaled carbon dioxide and providing a clear pathway for inhaled air.

For this purpose, two exhalation non-return filtration valves are separately utilised and are independent from the main filter system intake.

When exhaling, the pressure build-up in the mask is naturally released through the valves creating a vacuum in the mask, allowing for fresh air to flow into the mask.

In the attached Creamer Media video, Dunford and Allnutt provide additional in-depth insight.