Stepping up safety in times of crisis

REINHARDT SWART Building a positive African future is not possible without including a tangible zero harm approac

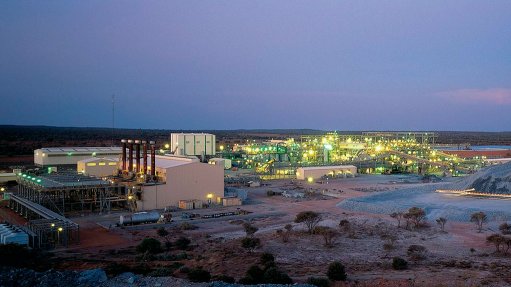

THE AFRISAM WAY Tanga Cement has recorded millions of safe working hours over the past four years

A safety and health culture should be an enabler for all employees and stakeholders across any operation to live safely, says construction materials supplier AfriSam Group subsidiary Tanga Cement Company MD Reinhardt Swart.

“We should enable our people to live the safety culture,” he tells Mining Weekly, adding that it boils down to a company culture based on values and communication.

Building a positive African future is not possible without including a tangible zero harm approach and prioritising the health and safety of all stakeholders.

Driving a value-based culture is critical to ensure the measures in place for zero harm are tangible and simple, and effectively protect the employees on the front line, he says, highlighting the effectiveness of the ‘AfriSam Way’, wherein safety is firmly entrenched in the company culture.

While safety and health is not about doing the bare minimum at a high level, it does require a lot of work and there is a need for high-level leaders to drive the process to ensure that employees go home safely every day.

It is a complete culture change, something that AfriSam started with in the group years ago.

Each of the companies’ offices and operations has stringent safety structures in place and specific initiatives to ensure best practice, with safety statistics continuously monitored and early warnings in place to facilitate proactive addressing of concerns.

“We place strong emphasis on a health and safety culture with stringent rules and regulations which are as effective in their home lives as they are in the workplace,” Swart explains.

The AfriSam Way includes the ability to communicate across every level.

“Whenever you talk to, debate with or challenge someone, it is to learn, or to teach in some cases, but never to hurt. This means people talk to one other to learn, and they start to listen differently.”

It is the principle of enabling your employees to live safely, with the potential of the safety culture on ‘the inside’ impacting the culture on the outside.

Citing its Tanga Cement operations, in Tanzania, a country with citizens that generally take risks, millions of safe working hours have been recorded over the past four years.

Following two fatalities in two separate incidents in January 2016, the company achieved 5.2-million hours of zero lost-time injury (LTI) up until August 2019, when there was one LTI reported.

Since then, the company accumulated another one-million hours of zero LTI by the end of March.

The operations have two “safety coaches”, for the day and night shifts, to coach employees on safety and ensure they understand the roles the initiatives play in keeping them safe and why and how certain risks or actions could cause them harm.

The culture adoption and principles extends to all contractors, suppliers and visitors.

“If you talk sustainability, you have to look after your people and the environment, inside the operations and outside,” he explains, noting a shift change in the community in which Tanga operates.

The safety programmes within the operations have started to impact how employees lived and responded to safety outside of the operations.

He cites examples where citizens often engage in risky behaviour such as drivingmotorcycles at high speeds, with no helmets, ineffective brakes or no lights.

“In 2016, we started with the value-based safety culture change. By mid-2017, many people were starting to wear helmets on motorcycles. The positive safety culture spreads into the communities,” he comments.

Covid-19

The health and safety of employees has been highlighted as the Covid-19 pandemic spreads across the world.

At Tanga, the company trained its health and safety coaches in Covid-19 procedures as soon as the pandemic reached Tanzania.

The coaches now teach physical distancing and hygiene, in addition to World Health Organisation or country-specific Covid-19 mitigation recommendations.

Swart points to an example wherein the employees themselves now sanitise the operation’s employee-transport vehicles and any surfaces being touched, and how the workers are more aware of how the virus spreads and the means to curb it.

Tanga also halved its workforce on site and instituted initiatives for the employees who can work from home to do so.

“We closed our office in Dar es Salaam, with only a receptionist in place diverting visitors, suppliers and customers, while the sales force is working remotely and in the market.”

At the plant, the shift workers and maintenance crew has been split into teams to cover two-week shifts, with half the workers operating the plant under strict measures and the other half at home but on standby.

Should one of the shift teams experience any Covid-19 infections, the second team can take over to ensure smooth, uninterrupted operations.

There have been no reports of Covid-19 cases as the second team completes its first two week shift, however the company has systems and contingency plans in place to mitigate any possibility.

In South Africa, AfriSam’s operations have been on care and maintenance since March 27, with a Covid-19 task team in place to ensure the company complies with all the directives.

“As soon as the state of disaster were declared, we started to get everybody to work from home where practical,” he says, noting the company bought 140 laptops, which was distributed to get as many people out of the office as quickly as possible.

“By the time lockdown happened a week later, we had the ability to give everybody laptops and they were working from home.”

Some 40 000 sachets of surface concentrate sanitiser were issued to persons, contractors or suppliers, that had access to its site – both before and during the lockdown – to take home.

The operations were stopped and placed on care and maintenance, with core essential operations continuing through a small team on site, which is constantly monitored and screened.

The group also disseminates verified, reliable information to its employees on a daily basis to mitigate the impact of false news flooding the system externally.

As the Covid-19 pandemic is unlikely to be resolved by the time operations reopen and lockdown lifts, AfriSam has several initiatives and plans in place to keep its employees safe and its operations sustainable, Swart concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation