Single technology provider maximises project value

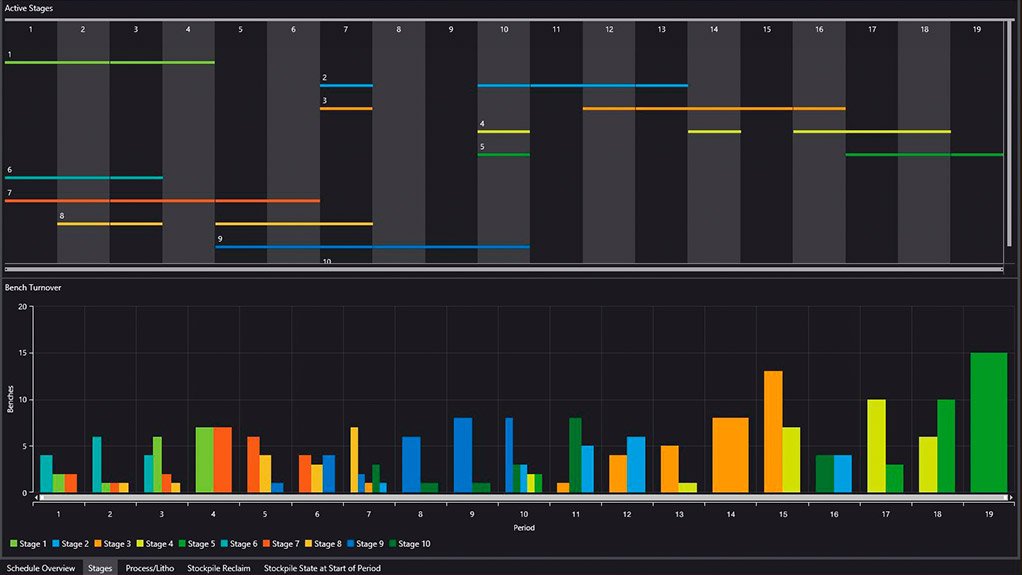

REPORT GENERATION Reports are generated to easily visualise mine progression

MINE VISUALISATION Maptek Evolution generates production plans while optimising the haulage fleet and the overall shape of waste landforms

Simplification of ownership, access to a single technical support helpdesk and streamlined workflows are key advantages of using a single technology provider, says mining hardware and software company Maptek.

Using a single provider will also lessen import and export routines, resulting in a reduced chance of errors arising from reformatting data, the company says, noting that it provides technology solutions to cover the entire mining execution chain.

The Maptek Evolution strategic and tactical mine planning tool integrates the workflow between mine design and scheduling. It creates dynamic, cost-effective schedules from a resource model and employs a cutoff grade optimisation approach to ensure project value is maximised.

With this software, users can rapidly run thousands of scenarios before choosing the best option.

Users can also run block- by-block scheduling to deliver granular information, and holistic scheduling to fully exploit fleet and resources.

Maptek states that scheduling across planning horizons helps operations hit blending targets and meet customer product specifications, as different attributes can be combined to get the right mix to increase value.

Maptek Evolution also generates production plans, while optimising the haulage fleet and the overall shape of waste landforms. Haul routes can be defined with calculated cycle times, productivity and fuel consumption.

Further, users also have access to all the relevant information contained in project block models for scheduling ensuring that when the geological block model changes, the schedule is automatically updated.

“Tighter integration [of Maptek Evolution] with Maptek Vulcan mine planning software is high on the development agenda. “An early inclusion is phase optimisation, which is a much sought after tool, [as it] will provide the most practical phase design for the mining schedule,” says Maptek scheduling solutions manager Steve Craig.

“As we continue to develop Maptek Evolution, we aim to maximise the value of the client’s mine, taking into account the complexities faced every day. “These include multiple resources, staged release strategies, fluctuating commodity prices, variable recovery and rehabilitation costs,” he adds.

Maptek Evolution improves productivity for any operation and can be used for a range of commodities, including iron-ore, copper, uranium and gold. Mine planners and management must ensure that their decisions are based on profitability from the start of the project.

“Whether the client is developing long-term or day-to-day plans, they need to know what is possible and where and when to mine. “Maptek products are the tools required to model resources, design a mine and keep information up to date,” says Maptek Africa and Europe GM Duncan Lee.

“Systems which support live decision-making break through the communication barriers between engineers, surveyors, supervisors and operators,” he says.

PerfectDig

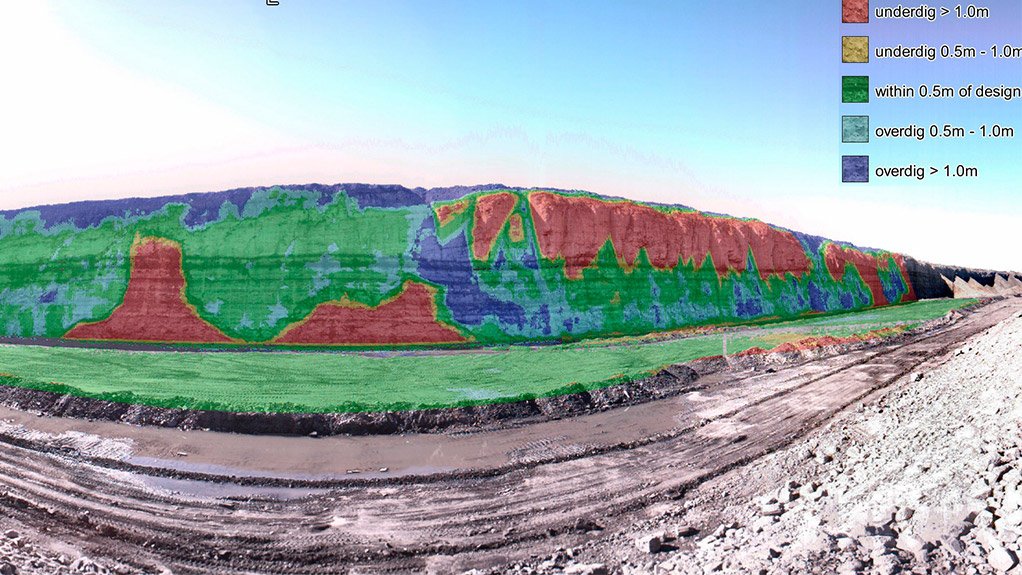

Meanwhile, Maptek’s design conformance system PerfectDig generates scenes taken from three-dimensional laser scan data and compares these with a mine design in real time.

PerfectDig is applicable to any type of mine with exposed excavation surfaces, including dredging operations. The system is easy to use. Laser scan registration, photo correction and obstacle removal are all fully automated. Excavation can be monitored as it progresses, a digital audit trail can be maintained, and adjustments can be identified to allow better conformance to design.

PerfectDig promotes efficient allocation of resources and results in improved wall stability and safety.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation