IPR's dewatering plan saves the day at iron ore mine

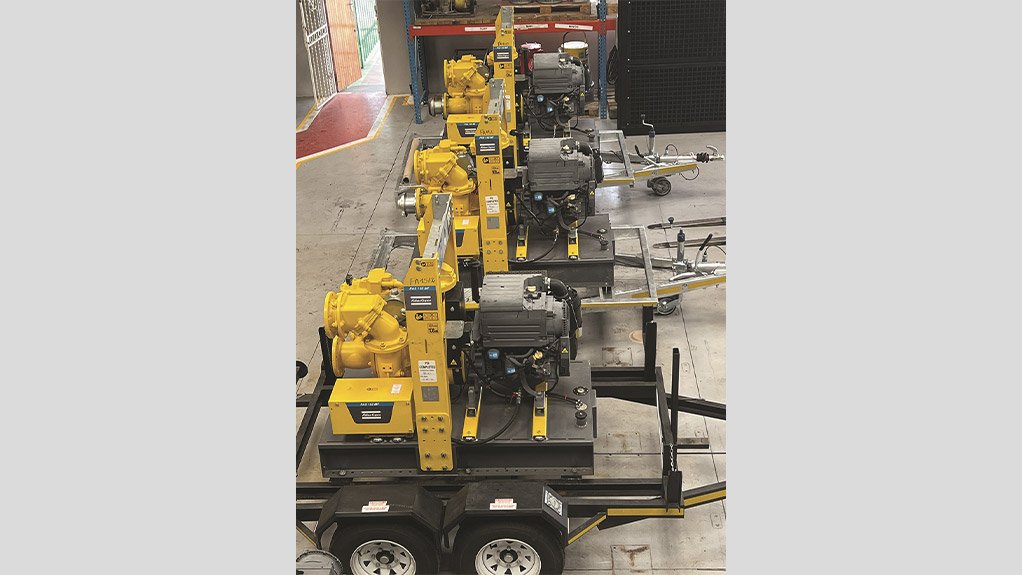

The IPR team prior to the pump leaving the company's facility in Jet Park

IPR is the Atlas Copco master distributor for its range of dewatering pumps

When flooding at an iron ore mine in South Africa’s Northern Cape province meant it could no longer access the floor of one of its pits, it called in IPR for a sustainable solution.

Rental Development Manager at IPR, previously known as Integrated Pump Rental, Ruaan Venter says the solution began with a dewatering plan. This was vital, as the mine had experienced challenges with groundwater ingress for many years – and these were not being resolved.

“A common open pit dewatering method is to use pumps to extract water from the lowest levels of the mine,” explains Venter. “However, it is often not enough to perform only this step. Rather, the whole groundwater table around the mine has to be lowered, so that the pit is not continually filled with incoming water.”

He says IPR’s eight years of experience in designing and manufacturing dewatering systems has given it a depth of insight into efficient and reliable groundwater control. The company’s approach is to apply best practice in dewatering applications, and not just send a pump set to site without a good understanding of the operating conditions and the specific challenges being faced.

“In this case, we identified that the primary issue was the application of incorrect dewatering pumps, which were not performing the duty required,” he says. “IPR implemented a programme to assess and then repair the existing pumps on site – bringing them up to OEM specification so that they would perform reliably and deliver the expected results.”

In line with the dewatering plan, the mine’s own fleet of pumps was supplemented by a custom offering from IPR. This involved some units being purchased outright from IPR, and other pumps taken on a long term rental agreement. Venter notes that dewatering has seasonal variations, and this could mean that some pumps stand idle for several months during dry periods.

“Our rental programme is offered in recognition of this to relieve customers of the cost of owning equipment that is not optimally utilised,” he says. “Instead, we supply pumps sets that are fully kitted out according to the customer’s requirements – and they are ready for operation.”

He points out that the plan for this mining customer also included an appreciation of water quality and characteristics.

“Groundwater and process water contain abrasive and corrosive elements in varying quantities,” says Venter. “These have an adverse effect on pump performance and life – and need to be built into the pump specifications.”

A key aspect of the plan was therefore to ensure that all pumps performed optimally, to eliminate the risk of repeated flooding. IPR is therefore maintaining all pumps on site, including its own fleet and those belonging to the mine.

“Well-matched solutions help to maximise the longevity and efficiency of the system and also optimise cost-performance ratios,” he says. “IPR ensures we deliver these results, by supplying a complete dewatering package made up of the pump, engine or motor and couplings – as well as auxiliary equipment such as vacuum pumps, control panels and monitors. This service delivers high head pumping where the water levels must remain low for continuous production reliability.”