Anglo’s impressive Quellaveco copper project 34% complete

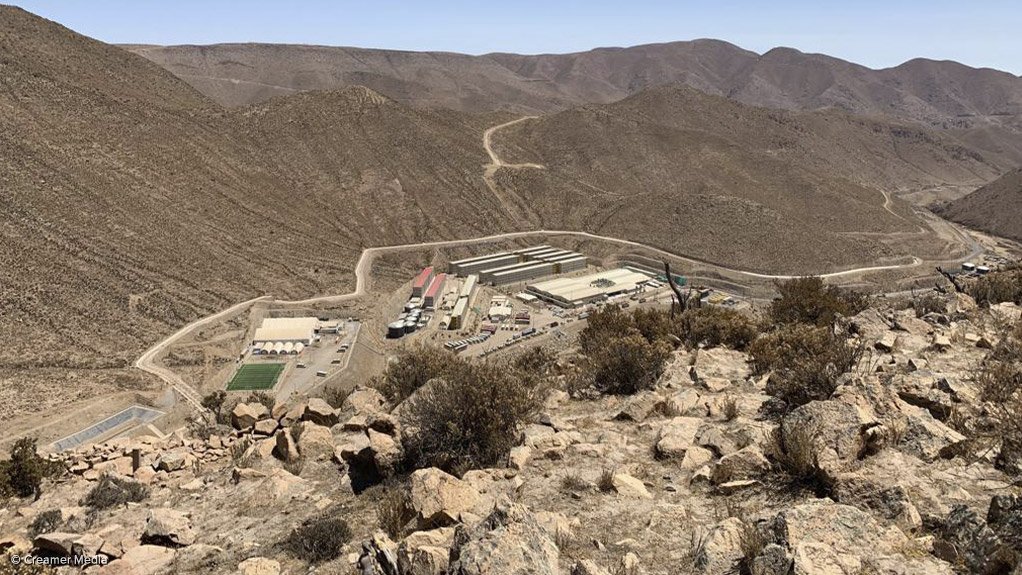

Anglo American's Quellaveco project, in Peru

Photo by Creamer Media's Martin Creamer

LIMA, Peru (miningweekly.com) – Anglo American’s impressive Quellaveco copper mine project in the Moquegua region of southern Peru is 34% complete and on schedule for first production in 2022.

The $5-billion project, which has been under way for 14 months following full notice to proceed on August 1 last year, is located in one of the world’s largest undeveloped copper deposits.

“The project is effectively procured out and contracted out. All the major contacts have been placed and all the major equipment has been procured,” Anglo American project director Christoff Kuhn said on site on Tuesday, where Mining Weekly Online was part of a visiting international media delegation.

The project involves the building of a new 60-million-cubic-metre dam in the High Mountain region and a 95 km overland gravity-fed pipeline to deliver water to the Quellaveco mine area, where an opencast mine is being developed along with a primary crusher, overland conveyors and truck maintenance workshops, for which platforms are being completed.

A key accomplishment at Quellaveco is that the river diversion tunnel has been commissioned.

The barrier is visible and an improved quality and volume of water is already now available to local communities.

Water for the operational phase is from two sources in the High Mountain region, with 80% arising from the Titire river, which was unfit for human, livestock or agricultural use owing to naturally high levels of salt, boron and arsenic, and the remaining 20% coming from the dam and reservoir under construction.

A major structural cost advantage is that the orebody has been largely uncovered by river erosion and the overburden stripped by Mother Nature, leading to very low strip ratio.

The tunnel system being constructed will transport ore from the mine to a concentrator plant in the valley next to the mine.

Ore reserves of 1.3-billion tonnes, containing 7.5-million tonnes of copper give Quellaveco a reserve life of 30 years, with potential for further extension given its estimated additional mineral resources of 1.6-billion tonnes, containing six-million tonnes of copper.

The flotation process will be used to produce copper concentrate, as well as a molybdenum byproduct.

Allowances for coarse particle separation have been made on the flotation circuits to make it relatively easy to incorporate the more efficient and lower water consumption higher technology into the system.

“That’s currently in study phase and once that’s proven and the financial viability is guaranteed, we’ll probably proceed with that,” Kuhn said.

From the processing plant at Papujune, a second tunnel system will be used to transport tailing to an adjoining valley, where the starter dam is ahead of plan for the rainy season. More than 90% of the earthworks at the processing plant have been completed.

On site during the visit of Mining Weekly Online was structural steel that has been brought in from China as well as some parts for the mining fleet.

At its initial nameplate throughput rate of 127 500 t/d of ore, Quellaveco is expected to produce an average of 300 000 t/y of copper over its first ten years of operation, at a cash cost of $1.05/lb of copper.

Concentrate will be trucked 165 km to the port facility, where modifications will see to a dedicated ship-loading facility for the project, located at energy company Engie’s facility, where there will be storage and a pipe conveyor.

The project is 60% owned by Anglo American with Mitsubishi Corporation a 40% strategic partner.

Anglo American’s marketing division will do marketing of the copper concentrate.

At the peak of construction, about 12 000 people are expected to be employed and 2 500 people will be employed permanently once the mine is in production.

Quellaveco has accommodation facilities for 9 000 people.

Water-saving initiatives are apparent on site at Quellaveco, with evaporation balls already covering ponds to reduce evaporation exposure.

The project has a mine life of 30 years, with potential for further extension.

There is support for the project among the local communities as a result of an innovative 18-month consultation with local authorities and community representatives from the Moquegua region.

All nonqualified workforce on the project have been recruited locally and more than $114-milllion worth of goods and services been procured from Moquegua.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation