Typical Pump Performance Curve

When a Submersible pump is installed and in operation, in most cases the pump is completely submerged and out of sight while very little attention is paid to the actual operating costs involved.

Before purchasing a submersible pump, the main consideration should be the total cost of ownership, besides the purchase price of the pump the cost of power usage, maintenance as well as the cost involved in the loss of usage should also be taken into consideration.

There are many factors that must be considered which will have a drastic influence on the life expectancy and cost of the submersible pump and if not properly addressed will result in unnecessary costs which could have been avoided.

Pumping System: The submersible pump forms part of a pumping system and it is essential that the pumping system be evaluated to ensure that that the system has the ability to achieve the desired result at the minimum overall costs. In the design of the pumping system certain information would be required to ensure the optimal performance. Starting off with the liquid that needs to be pumped the volume of the liquid must be determined accurately. The next step would be to decide where the liquid needs to be pumped to and if part of a process the pressure requirement of process also needs to be known.

If the example of a borehole submersible pump is used, then the maximum volume that can be pumped cannot be more than the inflow of water entering the borehole from the aquifer. If the borehole pump is also to be used to supply water to an irrigation system, then the pressure that the sprayers would require to operate effectively also needs to be included when determining the total discharge pressure of the borehole pump. The pipe system will also be a factor to be reckoned with when the total discharge pressure is calculated, as the friction losses in the piping system must be overcome and will form part of the total discharge pressure.

Incorrect pipe diameter will contribute to both unnecessary wear and high energy costs when pumping a specific volume and it is essential that the pipes are sized to achieve the minimum energy usage while achieving the optimum flow. Once the pipe diameter has been determined other fittings such as valves, bends, and T-pieces etcetera must also be considered to determine the system friction losses.

Pump Selection:

Pump Duty Point: When determining the duty point at which the pump will operate the following needs to be considered:

- The total discharge pressure which will be the sum of vertical pressure, the pressure to overcome the friction loss and the required process pressure.

- The required flow rate and the composition of the liquid to be pumped as well as the total discharge pressure has to be determined for the pump to be selected.

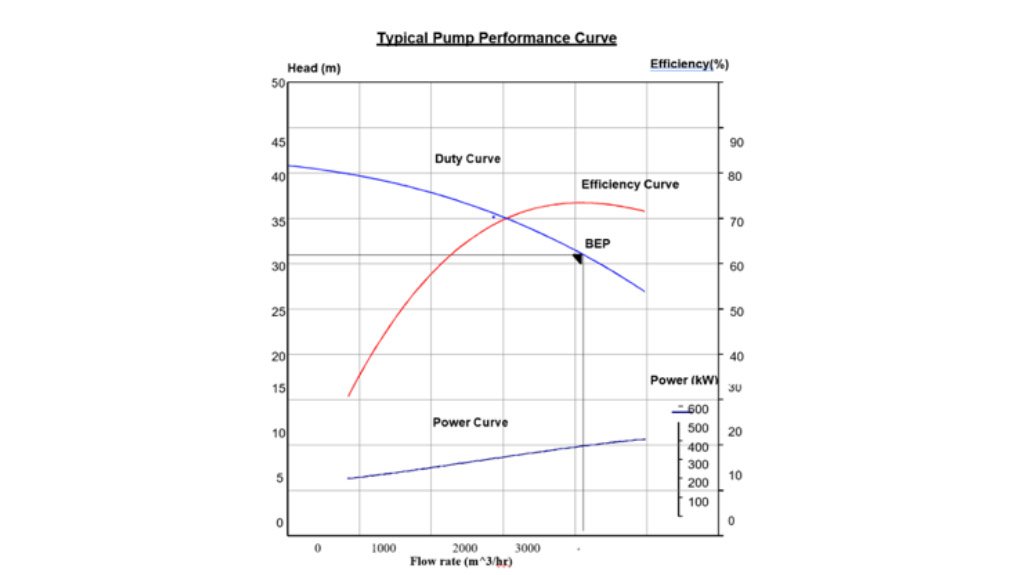

- All pumps are to be tested, and a pump curve is generated with the pressure (referred to as the HEAD) in “kPa” or “Meter” on the Y axis and the flow rate in “m3/h” or “l/s” on the X axis as well as the Power Absorbed is plotted on the Y axis (kW) for the efficiency of the pump to be determined.

When evaluating the pump curve, a point will be identified as the “Best Efficiency Point”, and it is at this point where operated giving the optimum delivery using the least power and it is at this point that the pump selected must operate.

Material of Construction: The product being pumped can also influence the total cost. In most cases submersible pumps are used to pump water and all pump curves are generated for this condition.

Should the product contain solids or a chemical substance, a detailed analysis of the product should be done to determine the required material of construction of the pump.

With solids present in the liquid the concentration, Specific Gravity (SG) and particle size is important while with chemical substances the Ph and a chemical composition will be important and must be established to ensure that the submersible pump is constructed from a material that will be capable of pumping the specific liquid with the minimum wear and be able to withstand the effects of erosion and corrosion.

When pumping a liquid containing solids and a Ph higher than four (4) a hydraulic end manufactured from 28% Chrome castings which had been hardened could be used successfully. Should the Ph be less than four (4) Duplex Stainless-Steel casting, such as a Cd4CMu could be used.

When pumping liquids containing chemicals the material of construction of the pump must withstand chemical corrosion of the parts. The chemical composition of the liquid as well as the temperature will determine which material should be used.

When liquid that has both solids and is acidic needs to be pumped, certain duplex Stainless Steels such as Cd4CMu should be used, but it is advisable to consult an expert with regards to the material of construction of the submersible pump.

It is of utmost importance that when pumping liquids containing solids to ensure that the pump operates at the Best Efficiency point. The wear rate that will occur at the BEP will be at a minimum and will contribute to both a cost saving on power consumption and a longer pump life.

Inflow Conditions: Most submersible pumps rely on the product being pumped to dissipate the heat generated from the electrical winding and should the in-flow to the submersible pump stop the pump will overheat and burnout of the electrical winding will result. The major cause of failures of submersible pumps is due to the overheating of the Electrical Windings.

Quite often the inflow rate into the submersible pump will change or vary and could result in the pump running dry and under these conditions the stator windings will build-up heat and finally burn out if the heat is not dissipated.

To solve the overheating of the stator winding the heat generated by the winding must dissipate to the atmosphere and this can be achieved by using a submersible pump with the stator housing filled with oil assisting with the dissipation of the heat from the winding to the atmosphere.

Submersible pumps could also have a “bottom suction” configuration design which is mainly used to remove liquids containing solids.

Mechanical Seals: All submersible pumps are fitted with mechanical seals to keep the liquid being pumped from entering the stator housing and damage the electrical winding. Most submersible pumps are fitted with two mechanical seals. The mechanical seals also require that the heat generated by the mechanical seals faces be removed and this is also achieved by having the mechanical seal chambers filled with oil which will lubricate the seal faces as well as to dissipate the heat generated.

To extent the lifespan of the mechanical seals, double lip seals are also installed below the lower mechanical seals and a deflector is installed on the shaft below the lip seals to displace larger solids and protect the lower clamp plate.

Shaft vibration: This is also one of the major causes of mechanical seal failures and for this reason the impeller must be balanced and all the radial forces on the impeller be balanced out. By utilizing a double discharge volute design all the radial forces on the impeller will be balanced out.

Electrical Control Panel: Should the submersible pump be overloaded to the extent that the power absorbed being greater than the maximum power that the electrical windings had been designed for, the windings will also burn out. To avoid this an overload relay will be fitted to the electrical control panel. In most cases additional protection relays are also installed in the electrical control panel which are as follows:

- Mechanical Seal Failure Detection: This is achieved by having probes installed in the stator and the lower seal chamber. The probe will measure the conductivity of the oil in the chambers and should the seal fail the oil will be contaminated and become conductive.

- Thermistors: PT100 probes are installed in the stator housing as close to the bearing as possible to detect bearing failure and stop the submersible before serious is caused to the pump.

If all the above mentioned points are adequately addressed the total cost of ownership of the submersible pump will be kept to a minimum.

Hazleton Pumps