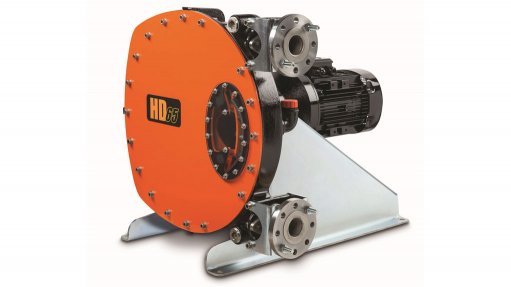

SUITED TO MINING The Abaque series of perastaltic pumps can handle slurries that contain up to 80% solids with ease

Multinational pumps and pump-related solutions provider PSG Dover has designed new models of its Abaque series of peristaltic pumps, which have been specifically geared to meet the challenging requirements of the mining industry, partially owing to a stronger and more durable rotor design and patented hose holding system.

Featuring a sealless design that eliminates leaks and product contamination, Abaque pumps are ideally suited for numerous mining applications, including waste- water, slurry transfer, thickener underflow, recirculation, reagent dosing, froth flotation, cyanide processing and filter press.

The ability to handle slurries that contain up to 80% solids with ease, in addition to no moving parts making contact with the product, ensures that Abaque pumps offer significant advantages over their competitors, says PSG.

These self-priming pumps can operate forward or in reverse and offer suction-lift capabilities of up to 9 m, as well as the ability to run dry without adversely affecting performance, pressure and accuracy. Abaque pumps are constructed from ductile iron and stainless steel, allowing a higher discharge pressure to 15 bar.

The Abaque series’ pumping action is achieved by compression of a circular

loop of elastomeric hose with two diametrically opposed rotating shoes. This

rotational motion forces the fluid in the hose to move ahead of each shoe.

When each shoe reaches the end of the loop, the reinforced hose immediately returns to its original shape, ensuring suction and priming, creating a strong vacuum pulling more fluid inside.

This results in a pump that features higher performance, lower water consumption, reduced downtime, lower maintenance costs, increased reliability and the ability to handle the toughest pumping challenges, including extremely abrasive and aggressive fluids, states PSG.

The hoses are available in natural rubber, which is highly resilient, with excellent abrasion resistance and strength, Buna-N, which is wear-resistant to oily products, ethylene propylene diene monomer rubber, with a high chemical resistance facilitating the handling of concentrated acids, alcohols and ketones, and Hypalon, which is resistant to chemicals, extreme temperatures and ultraviolet light.

Abaque pumps are available in 13 different sizes, with flow rates ranging from 15 ℓ/h to 77 000 ℓ/h and are distributed in Europe and Africa through PSG member company and positive displacement pumps manufacturer Mouvex.

PSG forms part of diversified manufacturing corporation Dover and is a leader in the manu- facture of pumps, systems and related flow-control solutions for the safe and efficient movement, measurement and control of critical and valuable materials within targeted markets.

The company’s products are manufactured on three continents – North America, Europe and Asia – in facilities that practise lean manufacturing and are International Organisation for Standardisation-certified. PSG employs 1 400 team members at 19 global locations and supports more than 1 700 channel partners in more than 100 countries.