NEW SHAFT BORING ENLARGEMENT TECHNOLOGY Murray & Roberts Cementation’s new shaft-boring machine represents “the next generation” of rodless shaft enlargement machines

Mining contracting company Murray & Roberts Cementation will showcase a new series of shaft-boring machinery for shaft enlargement (SBE) at the Investing in African Mining Indaba, which will take place at the Cape Town International Convention Centre from February 9 to 12.

Murray & Roberts Cementation business development director Allan Widlake tells Mining Weekly that, owing to the renewed emphasis on mechanisation in the mining sector, Murray & Roberts Cementation and German mining construction company Thyssen Schachtbau, in conjunction with German tunnel-boring machine manufacturer Herrenknecht, introduced a new SBE system in June last year to the local market.

He says the new machine represents “the next generation” of rodless shaft enlargement machines, or the so-called V-Mole technology.

The SBE system facilitates high sinking speeds of 6 m/d to 10 m/d, with the added safety benefit of the shaft being supported as it advances.

Widlake says Murray & Roberts Cementation believes the technology strengthens the local emphasis on mechanisation, as the technology guarantees a significantly higher confidence level in terms of scheduling and productivity.

He further notes that Murray & Roberts Cementation has entered into many discussions with local mining houses and consultants.

“There are opportunities locally and across the border in the future with regard to using the technology, which cover the full spectrum of commodities, including diamonds, copper and platinum,” says Widlake, adding that he does not regard the remoteness of many African mining operations as a constraint.

“A major benefit is that we use fewer people to realise a complete shaft system. While this would normally require about 150 people, the new technology reduces this requirement to between 75 and 80 people in total.

He adds that, in brownfield operations, conventional raise borers have a limited capability in shaft diameter and depth, particularly in terms of production and ventilation shafts.

“From a geotechnical point of view, if a raise borehole is located in poor ground conditions, it runs the risk of the shaft collapsing, while the hole advances. The next-generation SBE guarantees shaft stability, as the hole is supported during sinking,” explains Widlake.

Research and Development

Widlake says various criteria were highlighted during the development process of the SBE.

“We wanted to ensure it was user-friendly and easy to maintain, with the most sophisticated electronics being confined to the laser guidance system.”

Herrenknecht responded to this design challenge by incorporating components that had been tried and tested in modern tunnel-boring machines.

“It was a perfect integration of elements. Murray & Roberts Cementation and Thyssen Schachtbau contributed their operational and practical functional expertise, while Herrenknecht specified how the technology would be put together,” explains Widlake.

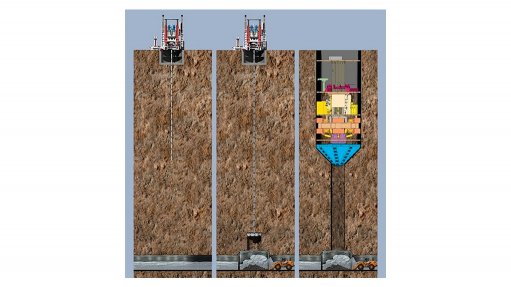

He notes that the system comprises three construction phases. The first involves drilling a pilot hole using directional drilling, the second enlarging the pilot hole to an advance hole diameter of between 1.78 m and 2.4 m through raiseboring, and the third is the reaming of the advance hole to the final shaft diameter from top to bottom.

All cuttings are transported through the advance hole to the undercut level.

“This particular sinking method depends on us having an access drift available at the lowest part of the shaft, along with sufficient debris clearance capacity for the excavated material,” states Widlake.

He adds that there must also be continuous downcast ventilation for the duration of the sinking operation.

“Raiseboring and shaft-support operations are carried out simultaneously, with the SBE operated from a central control stand on the operator’s platform. The only limitation in terms of the boring depth is the pilot hole and not the shaft boring machine.”

Widlake emphasises that, as long as there is an undercut level for constructing a raise-bored advance hole, the shaft boring depth is essentially limited to the maximum depth modern raise borers can handle.

The additional benefits of the SBE system include zero blast damage to the shaft side walls, which allows for a cost-effective support system – in the form of concrete or shotcrete lining – to be applied; reduced project costs; and achieving the earliest possible commissioning date.

Widlake believes the introduction of the new technology to the mining industry is greatly needed, along with a different approach to mining operations.

“Mining companies are looking for more certainty on their programmes and costs and for a safer outcome for their projects. This equipment definitely fulfils those requirements,” he asserts.

Widlake adds that tunnel boring technology has developed to such an extent that it is highly reliable, particularly in selecting components, such as drives and bearings.

“It’s not as if we are reinventing the wheel in terms of the applied technology, as this offering is, in essence, standard off-the-shelf components from Herrenknecht,” he says.

Widlake concludes that once the SBE unit has completed a particular project, it can be disassembled and recustomised for another project.